Starlight Torch Kit System

Starlight Torch Kit System Specification

- Drive Motor

- Stepper

- Product Type

- Industrial Cutting System

- General Use

- For precise metal cutting

- Material

- MS, SS, Aluminium

- Type

- Torch Kit System

- Capacity

- Heavy Duty

- Weight (kg)

- 35 kg

- Computerized

- Yes

- Automatic

- Semi-Automatic

- Cutting Speed

- 06500 mm/min

- Cutting Thickness

- Upto 50 mm

- Cutting Function

- Plasma/Flame Cutting

- Cooling System

- Air

- Drive Type

- Stepper Motor

- Voltage

- 220V/380V

- Dimension (L*W*H)

- 550 x 400 x 500 mm

- Feature

- Modular design, high-efficiency, portable

- Color

- Metallic Grey

- Motor

- High Torque Stepper

- Mechanical Precision

- 0.1 mm

- Cutting Method

- Plasma or Flame

- Control System

- Digital CNC

- Cutting Material

- Mild Steel, Stainless Steel, Aluminium

- Cutting Area

- 400 x 400 mm

- Gas Requirements

- Oxygen/Acetylene or Air

- Safety Features

- Emergency Stop, Overload Protection

- Mounting

- Desktop/Floor Mount

- Power Consumption

- 3.5 kW

- Display

- LCD Digital Panel

- Operating Temperature Range

- 5C - 45C

- Torch Type

- Single Head

- Finish

- Corrosion Resistant Coating

- Portability

- Portable Easy to Transport

- Input Frequency

- 50/60 Hz

- Compatible File Formats

- G-Code, DXF

About Starlight Torch Kit System

Ever since our establishment in 2008, we are engaged in manufacturing and supplying excellent-quality Starlight Torch Kit System. It is engineered with great precision at our ultra modern facility under guidance and supervision of deft professionals. This system is highly demanded in various engineering and automobile industries for different purposes such as welding, brazing, hard soldering and heating, flame cutting, flame straightening, flame scarfing. Offered Starlight Torch Kit System is duly tested on well defined quality parameters to ensure full satisfaction of our clients.

Features:

-

Easily replaceable parts

-

Excellent functionality for years

-

High dimensional accuracy

Implementation:

Hand torch for welding, brazing, soldering, heating and flame cutting

Shaft diameter 15 mm

Welding range to 14 mm

Cutting range to 200 mm

Available with DIN and BS connections for all fuel gasses

Advantages:

Universal field of application thanks to a wide selection of different torch inserts

Especially robust version for extreme demands

High media flow rates

Easy operation of the mono-block valves

High durability due to brass valve housing

Ergonomic operation thanks to special handle shape

Low spare parts stocks required thanks to modular system

Scope of supply:

Complete welding and cutting kits

Individual units for welding, brazing, hard soldering and heating, flame cutting, flame straightening, flame scarfing

Accessories, consumable parts

Efficient and Accurate Metal Cutting

Experience exceptional precision with 0.1 mm mechanical accuracy in every cut. The combination of digital CNC control, a stepper motor, and a sturdy torch head guarantees sharp, repeatable resultseven on the toughest metals. The robust design minimizes vibrations, ensuring reliable performance for demanding cutting applications.

User-Friendly Digital Interface

Navigation is simplified with an LCD digital panel, making parameter adjustments and operation monitoring accessible, even for less experienced users. The platform supports popular file formats such as G-Code and DXF, so you can load your projects with ease and start cutting in just a few steps.

Designed for Safety and Convenience

Safety is paramount with integrated emergency stop and overload protection features. The lightweight, portable construction (at just 35 kg) and flexible mounting options allow the Starlight Torch Kit to adapt seamlessly to various work environments, whether you use it on the desktop or floor.

FAQs of Starlight Torch Kit System:

Q: How do I operate the Starlight Torch Kit System for metal cutting?

A: To use the Starlight Torch Kit, connect it to a suitable power source (220V/380V) and the required gas supply (Oxygen/Acetylene or Air). Load your cutting files in G-Code or DXF formats via the digital CNC control system, set your desired parameters on the LCD panel, and initiate the cut. The process is semi-automatic, ensuring ease of control from setup to completion.Q: What types of materials can I cut with this torch kit system?

A: The system is engineered for heavy-duty applications and supports plasma or flame cutting on mild steel, stainless steel, and aluminium. It can handle sheet thicknesses up to 50 mm, making it versatile for a range of industrial and workshop projects.Q: When is the Starlight Torch Kit most beneficial to use?

A: This kit excels when precise, efficient, and portable metal cutting is necessaryideal for fabricators, repair shops, and field operations. Its modular design allows for quick setup and relocation, making it suitable for both on-site and in-shop work environments.Q: Where can I install or use the Starlight Torch Kit System?

A: The kit is designed for portability and flexibility. It can be mounted on a desktop or floor in workshops, small fabrication units, garages, and even on-site at project locations across India, thanks to its compact dimensions and ergonomic build.Q: What safety features are included with the Starlight Torch Kit?

A: Safety is enhanced through an integrated emergency stop button and overload protection, providing immediate response in case of technical issues or improper operation. Additionally, the systems corrosion resistant coating ensures long-term durability in various operating conditions.Q: How does the digital control system benefit the cutting process?

A: The digital CNC control system allows for accurate programming and execution of cutting paths, accommodating G-Code and DXF files. This ensures minimal error and greater repeatability over multiple operations, while the LCD panel simplifies monitoring and adjustments during use.Q: What maintenance and usage processes should be followed for optimal performance?

A: For consistent performance, keep the torch nozzles clean, regularly check gas connections, and inspect the stepper motor and cooling fan. Ensure the kit operates within the recommended temperature range (5C45C), and always utilize the safety features provided during each operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

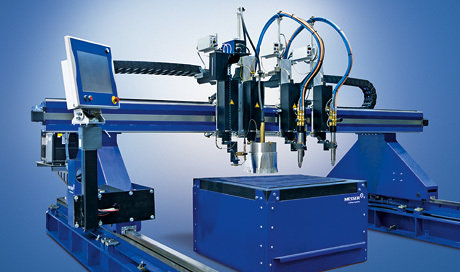

CNC Flame Cutting Machine

Capacity : Heavyduty industrial use

Feature : Other, High precision reliable cutting automated operation

Color : Blue

Cutting Speed : Adjustable

Cutting Function : Flame cutting, Other

Computerized : Yes

Metal Master Cutting Machine

Capacity : 2.5 Tons/Hour

Feature : Other, High precision, Heavy duty structure, Easy handling

Color : Other, BlueGrey

Cutting Speed : Up to 32 strokes/minute

Cutting Function : Other, Sheet Metal Cutting

Computerized : Yes

Hypertherm Plasma Cutting Machine

Capacity : High

Feature : Other, Smart Blade technology

Color : Blue

Cutting Speed : Fast speed for high productivity

Cutting Function : Other, Precision cutting

Computerized : Yes

ProBlade Cutting Machine

Capacity : Up to 50 sheets/hour (material dependent)

Feature : Other, Highspeed operation, Dust extraction port, Userfriendly touchscreen interface

Color : Other, Blue/Gray

Cutting Speed : Variable, up to 4000 mm/min

Cutting Function : Other, Precision straight and curve cutting

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS