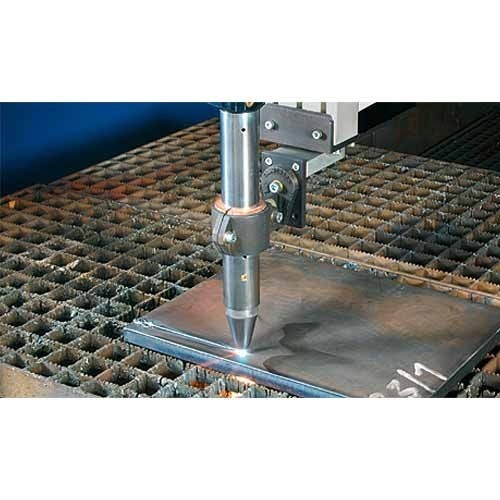

Metal Master Cutting Machine

Metal Master Cutting Machine Specification

- Drive Motor

- Induction

- Product Type

- Automatic Metal Shear Cutter

- General Use

- Metal Sheet, Plate, and Strip Cutting

- Material

- Mild Steel, Stainless Steel, Aluminum

- Type

- Metal Cutting Machine

- Capacity

- 2.5 Tons/Hour

- Weight (kg)

- 420 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- Up to 32 strokes/minute

- Cutting Thickness

- up to 6 mm

- Cutting Function

- Sheet Metal Cutting

- Cooling System

- Air cooled

- Drive Type

- Electric motor driven

- Voltage

- 220 V, Single Phase

- Dimension (L*W*H)

- 1200 x 600 x 1200 mm

- Feature

- High precision, Heavy duty structure, Easy handling

- Color

- Blue-Grey

- Motor

- 2 HP Electric Motor

- Mechanical Precision

- 0.2 mm

- Software Detail

- Compatible with most design software

- Cutting Method

- Hydraulic Shearing

- Control System

- Digital selector switch

- Cutting Area

- 870 x 280 mm

- Cutting Material

- Mild Steel, Stainless Steel, Aluminum

- Installation Service

- Available on request

- Safety Features

- Overload protection, Emergency stop switch

- Output Format

- Standard and custom options available

- Power Consumption

- 6 kW

- Noise Level

- <65 dB

- Input Frequency

- 50 Hz

- Lubrication System

- Automatic

- Display

- Digital LCD panel

- Operation Mode

- Continuous/Batch

- Table Type

- Slotted

- Operator Panel

- Touch-pad with emergency button

Metal Master Cutting Machine Trade Information

- Main Domestic Market

- All India

About Metal Master Cutting Machine

Manufacturer of a wide range of products which include metalmaster cutting machine.Leading Manufacturer and Exporter of MetalMaster Cutting Machine.

Key Features:

Flat Bed Design

Working widths up to 2500 mm

Maximum working length up to 8000 mm

Positioning speeds up to 35 m/min

Integrated cutting table (max. plate thickness 25 mm)

Specialised for precision plasma

Torch height Control System

IHS device THC for plasma cutting

Mechanical Pneumatic Press Torch Suspension

Practical and reliable, suitable for plasma cutting

CNC controlled z-axis with torch lifter OL 100SZ (Only with Global Controlplus)

Specialised for all precision plasma processes

Reliable Precision and Heavy-Duty Performance

Designed for industrial metalworking, this machine provides high mechanical precision and stability, ensuring accurate cuts with minimal error. Its heavy-duty structure and digital control system support both standard and custom cutting operations for various metal types including mild steel, stainless steel, and aluminum. The automatic lubrication system and durable electric drive make it ideal for continuous or batch production environments.

User-Friendly Controls and Safety Features

The Metal Master Cutting Machine integrates a digital LCD panel with a touch-pad operator interface that includes emergency stop and overload protection. Its computerized controls and digital selector switch allow intuitive programming and easy adjustments, enhancing both safety and operational ease. The automatic lubrication system and air-cooled design reduce maintenance needs, allowing operators to focus on productivity.

Flexible Installation and Software Compatibility

Whether you require standard or custom cutting setups, this machine comes with installation services available on request. It is compatible with most design software, streamlining the workflow from digital design to physical output. Dimensions of 1200 x 600 x 1200 mm ensure it fits well within standard industrial spaces, and the consistent output meets the demanding requirements of metal fabrication businesses.

FAQs of Metal Master Cutting Machine:

Q: How does the Metal Master Cutting Machine ensure high cutting precision?

A: The machine utilizes a hydraulic shearing method with computerized digital controls, ensuring consistent mechanical precision up to 0.2 mm. Its sturdy construction and digital selector switch support precise adjustments for high-quality, repeatable cuts.Q: What materials can I cut with this machine?

A: This cutting machine is suitable for mild steel, stainless steel, and aluminum sheets up to 6 mm in thickness. Its heavy-duty build and high-capacity output make it ideal for a variety of industrial metal cutting applications.Q: When is installation service available for this machine?

A: Installation services are available upon request when purchasing the machine. Our team coordinates with clients across India to ensure the setup is completed efficiently at your facility.Q: Where can the Metal Master Cutting Machine be used?

A: It is designed for use in industrial environments such as fabrication workshops, manufacturing plants, and metal service centers across India, where reliability and high throughput are essential.Q: What safety features are integrated into the operation?

A: Safety features include overload protection, an emergency stop switch on both the main panel and the operators touch-pad, and a robust build to minimize operational risks, ensuring the machine is safe for regular industrial use.Q: How is software integration handled with the cutting machine?

A: The machine is compatible with most common design software, allowing seamless import and execution of cutting patterns. This flexibility streamlines the workflow from digital design to fabrication.Q: What are the benefits of the automatic lubrication and air-cooling systems?

A: Automatic lubrication minimizes wear and extends machine life by consistently supplying vital components with oil. The air-cooled system maintains optimal operating temperature, reducing maintenance needs and ensuring continuous, efficient performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Straight Oxy Fuel Cutting

Product Type : Straight OxyFuel Cutting

Capacity : Industrial

Feature : Other, Robust construction, High precision, Easy to operate

Control System : Manual Control

Material : Other, Mild Steel, Stainless Steel

Type : Other, OxyFuel Cutting Machine

Plasma Cutting for Electrical Industry

Product Type : CNC Plasma Cutter

Capacity : 24hour continuous operation

Feature : Other, Highprecision, stable cutting, low maintenance

Control System : PLC based

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Type : Other, Gantry Type CNC Plasma Cutting Machine

Bevel Cutting Oxyfuel

Product Type : Bevel Cutting Oxyfuel

Capacity : Heavyduty, up to 1.5 m x 3 m sheets

Feature : Other, Heavy duty construction, automatic ignition

Control System : CNC Control

Material : Other, Mild Steel, Stainless Steel, Alloy Steel

Type : Other, Oxyfuel Profile Cutting Machine

Electrode Oven

Product Type : Oven, Welding Consumable Drying Equipment

Capacity : 5 kg / 10 kg / 15 kg

Feature : Other, Maintains electrode dryness, Portable, Energy efficient

Control System : Thermostatic

Material : Other, Mild Steel (Body)

Type : Other, Electrode Oven

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS