MultiTherm Eco Cutting Machine

MultiTherm Eco Cutting Machine Specification

- Drive Motor

- Stepper/Servo Motor

- Product Type

- Heavy Duty CNC Cutting Machine

- General Use

- Industrial Metal Sheet & Plate Cutting

- Material

- Mild Steel, Stainless Steel, Aluminum

- Type

- Plasma & Flame Cutting Machine

- Capacity

- 15 kVA (Depends on plasma source)

- Weight (kg)

- 1200 kg (approx)

- Computerized

- Yes

- Automatic

- Yes, Fully Automatic

- Cutting Speed

- up to 10,000 mm/min

- Cutting Thickness

- Plasma: up to 25 mm, Oxyfuel: up to 100 mm

- Cutting Function

- CNC Plasma & Oxyfuel Flame Cutting

- Cooling System

- Air Cooled

- Drive Type

- Rack and Pinion

- Voltage

- 415V AC, 3 Phase

- Dimension (L*W*H)

- 4000 mm x 2200 mm x 1700 mm

- Feature

- High-precision, user-friendly interface, robust structure

- Color

- Yellow/Black

- Motor

- Precision Stepper Motor

- Mechanical Precision

- 0.2 mm/m

- Software Detail

- Hypertherm ProNest (optional)

- Cutting Method

- Thermal (Plasma & Flame)

- Control System

- CNC Digital Controller

- Cutting Area

- 3000 mm x 1500 mm

- Cutting Material

- MS, SS, Aluminum, Alloys

About MultiTherm Eco Cutting Machine

Our range of products include multitherm eco cutting machine.Leading Manufacturer and Exporter of MultiTherm Eco Cutting Machine.

Key Features:

Working Widths up to 6 m

Rapid Speed up to 12M/Min reduces time between cuts

Cutting Speeds up to 12 m/min

Working lengths up to 38 m

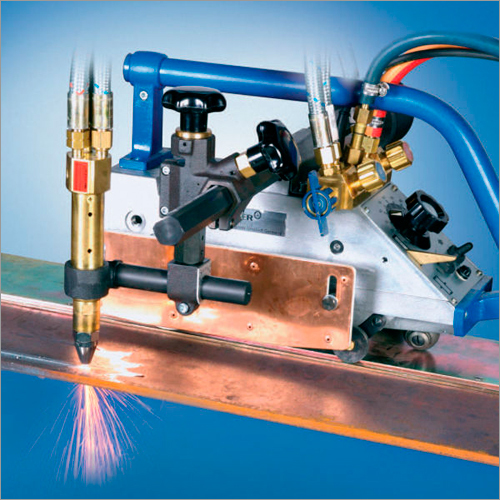

Cutting processes: Oxyfuel, Dry Plasma

Marking Processes: Punch marker, powder marking and single nozzle Ink-jet

Productive, compact

User friendly CNC control for fast set up

Synchronized bilateral longitudinal drives for good acceleration

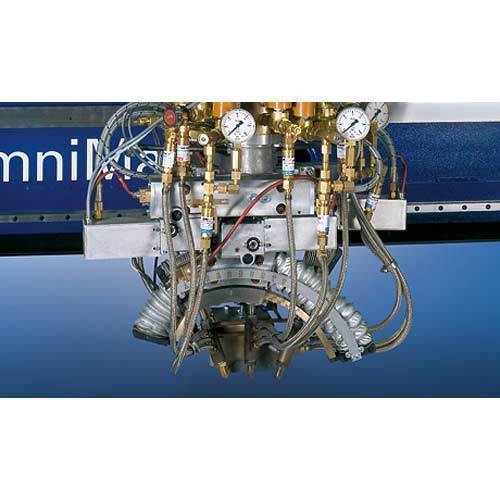

Automatic setting of all gas flows for oxy-fuel (Omniflow) and plasma

Reliable automatic height sensing

Symmetric wheel-housing for max. usable width

Parking space for unused torches over the wheelhousing increases effective cutting width

Length of wheel-housing gives maximum stability with minimum dead length

Electrical cabinet positioned over the wheel-housing so it is not exposed to thermal radiation from the cut plate increases lifetime

Electrical cabinet accessible from the side simplifies maintenance and service

Professional cutting at an affordable price

Precise and Versatile Industrial Metal Cutting

The MultiTherm Eco Cutting Machine delivers exceptional precision for industrial metal sheet and plate cutting. With the capability to perform both CNC plasma and oxyfuel flame cutting, it offers versatility for a range of materials, including mild steel, stainless steel, and aluminum. Robust construction and advanced control systems ensure high accuracy and repeatability, meeting the rigorous demands of medium to heavy fabrication workshops.

User-Centric Features for Efficient Operation

Equipped with a vivid LCD color touchscreen, automatic arc voltage torch height control, and seamless USB/LAN connectivity, this cutting machine is designed for intuitive use and easy integration into workflow. The digital CNC controller and compatibility with optional nesting software, such as Hypertherm ProNest, optimize cutting paths and reduce material waste, improving productivity for operators of all skill levels.

Built for Heavy-Duty Performance and Longevity

Engineered with a linear, heavy-duty precision guide rail and a durable rack and pinion drive system, the MultiTherm Eco is capable of high-speed, high-accuracy operationmax speed up to 15,000 mm/min. Its robust structure and reliable stepper or servo motor drive ensure long-term stability, while options for dry or waterworktables provide flexibility to suit a variety of workshop environments.

FAQs of MultiTherm Eco Cutting Machine:

Q: How does the automatic torch height control work on this machine?

A: The automatic torch height control (THC) uses arc voltage sensing to continuously maintain the optimal distance between the plasma or flame torch and the metal surface during cutting. This ensures clean, consistent cuts even if the sheet is uneven or warped, reducing the need for manual adjustment and improving overall cut quality.Q: What materials and thicknesses can the MultiTherm Eco Cutting Machine handle?

A: This machine is designed for a broad range of materials, including mild steel, stainless steel, and aluminum. When using plasma, it can cut up to 25 mm thickness, while the oxyfuel flame cutting mode allows processing of steel up to 100 mm thick, accommodating various industrial applications.Q: Where can I use the MultiTherm Eco Cutting Machine?

A: The MultiTherm Eco is suited for industrial environments such as fabrication plants, metal workshops, manufacturing facilities, and service centers. Its robust build and versatility allow it to handle high-volume production and custom fabrication tasks across a range of industries.Q: What is the process for cutting with both plasma and flame on this machine?

A: You simply select the desired cutting method (plasma or oxyfuel) from the CNC digital controller. Set the appropriate parameters according to the material and thickness, ensure the corresponding gas supply (air for plasma, oxygen and acetylene/propane for flame cutting), and load the cutting program via USB, LAN, or compatible software. The machine then executes fully automated, precision-controlled cuts.Q: What are the benefits of the LCD color touchscreen interface?

A: The LCD color touchscreen offers an intuitive, easy-to-navigate platform to control all machine functions, monitor progress, and adjust parameters. This enhances workflow efficiency, reduces setup time, and minimizes operator error, making the machine accessible even for users with limited CNC experience.Q: When should I choose plasma versus oxyfuel cutting on this machine?

A: Plasma cutting is ideal for cleaner, faster processing of thinner metals (up to 25 mm). Oxyfuel flame cutting excels when working with thick, heavy steel plates (up to 100 mm), where high-energy thermal cutting is required. The dual-capability design lets you select the most efficient method for your material and thickness needs.Q: What are the key advantages of using this cutting machine for industrial applications?

A: Key advantages include high positional accuracy (0.3 mm), advanced automation, robust mechanical construction, fast traverse speeds (up to 15,000 mm/min), and flexible connectivity options. These features together boost productivity, ensure repeatable quality, and support complex, high-volume or custom jobs in demanding industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Oxy Fuel Cutting

Material : Other, Mild steel, carbon steel, alloy steel

Cutting Function : Other, Oxyfuel gas cutting for steel and metals

Software Detail : Compatible with standard CNC programming software

Capacity : Varies by model, up to 2000 kg work support

Control System : Microprocessor/CNC based control panel

Voltage : 220V/380V/415V, 50/60Hz

Messer Plamill Software

Material : Other, Mild Steel, Stainless Steel, Aluminum

Cutting Function : Other, Plasma and Oxyfuel Cutting

Software Detail : Messer Plamill proprietary software

Capacity : Heavyduty Industrial

Control System : Integrated CNC

Voltage : 380V/50Hz

MS Sheet Cutting Machine

Material : Other, Heavy Steel Frame

Cutting Function : Sheet cutting, Other

Software Detail : Integrated CNC Software

Capacity : High

Control System : CNC Controller

Voltage : 220/380V

Secaator CNC Profile Cutting Machines

Material : Other, Steel assembly

Cutting Function : Profile cutting, Other

Software Detail : Integrated CNC software

Capacity : High precision cutting

Control System : CNC Control

Voltage : 220V/380V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS