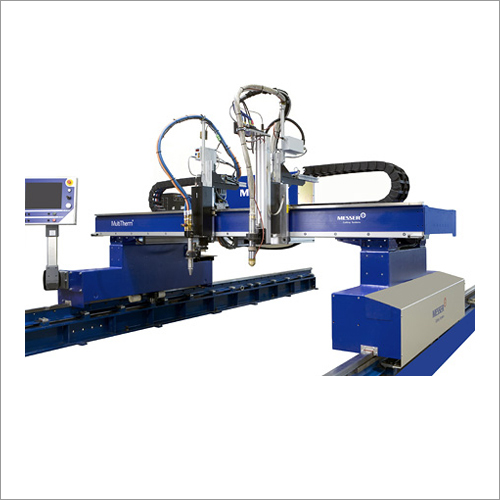

Messer Plamill Software

Messer Plamill Software Specification

- Drive Motor

- Precision Servo Drive

- Product Type

- CNC Plasma Cutting Software

- General Use

- Metal Sheet and Plate Cutting

- Material

- Mild Steel, Stainless Steel, Aluminum

- Type

- Automatic Cutting Machine

- Capacity

- Heavy-duty Industrial

- Weight (kg)

- Approx. 1200 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 0-8000 mm/min

- Cutting Thickness

- Up to 25 mm (plasma), up to 100 mm (oxyfuel)

- Cutting Function

- Plasma and Oxyfuel Cutting

- Cooling System

- Air Cooled

- Drive Type

- Servo Motor Drive

- Voltage

- 380V/50Hz

- Dimension (L*W*H)

- Approx. 3700 x 2200 x 1600 mm

- Feature

- High Precision, Multi-task Operation, User-friendly Interface

- Color

- Grey & Blue

- Motor

- AC Servo Motor

- Mechanical Precision

- 0.2 mm/m

- Software Detail

- Messer Plamill proprietary software

- Cutting Method

- Plasma Arc and Oxy-fuel

- Control System

- Integrated CNC

- Cutting Area

- 1500 mm x 3000 mm

- Cutting Material

- Steel, Stainless Steel, Aluminum

- Power Consumption

- 7.5 kW

- Working Humidity

- < 95% Non-condensing

- Safety Features

- Emergency Stop, Overload Protection

- Data Transfer

- USB, LAN, Network Supported

- Service Support

- Online & Onsite Support Available

- Torch Height Control

- Automatic

- Display

- 15-inch Industrial TFT Touch Screen

- Gas Console

- Fully Automated

- Repeatability

- 0.05 mm

- Software Compatibility

- DXF, DWG Import Supported

- Operating Temperature

- 0-45°C

- Installation Type

- Floor Mounted

Messer Plamill Software Trade Information

- Main Domestic Market

- All India

About Messer Plamill Software

We are a Leading Service Provider for the Cutting Software.We are Leading Service Provider of Messer Plamill Software.

Messer Plamill - the flagship plate processing center. Plamill is a unique combination of Plasma cutting, Milling, Drilling, Tapping & marking system. With rapidly increasing demand for components with multiple operations on medium thickness plates with speed, accuracy & reliability, Messer has come up with a unique state of art solution for its customers - "Messer Plamill with straight and bevel cutting. With a positioning speed of 36 meters per minute, multiple operations upto 50 mm thick plate becomes accurate & quick. High precision machine construction with dual beam provides a sturdy & long-lasting performance over the years. The prowess of this machine is the automatic tool change process, which can change upto 8 tools. This takes Plamill into higher levels of productivity by avoiding human intervention. By using helical milling & slot milling operations, bigger holes & slots can be made. The coolant is optimally spread for this operation to enhance tool performance. The unique marking system helps the user to mark the components with order numbers, part numbers, client name & component name for easy and unique identification. Messer CNC is a well known name in plasma cutting and edge preparation. When you want to detach the part from the plate, and make post cut edge preparation like V ,Y , X & I cuts, the front beam of this machine comes into action. It has a sophisticated and Robust plasma torch station which can be coupled with varieties of plasma sources depending on thickness and type of material to be cut. When you have components which involves plasma cutting, plasma beveling, counter sunk boring, drilling, Tapping, Marking, Thread milling, Slot milling, trust Messer Plamill.

For reliable production of high quality components, trust Messer cutting systems. Messer Cutting machines. No compromises.

Advanced User-Friendly Operation

The Messer Plamill machine is designed for ease of use with a 15-inch industrial TFT touch screen, offering an interactive experience for operators. The user interface allows for simple navigation and multi-task operation, enabling efficient setup and management of complex cutting jobs. Automated features like torch height control and gas console reduce manual intervention, streamlining the operation process and increasing productivity.

Superior Precision and Reliability

Built for heavy-duty industrial tasks, this system guarantees a repeatability of 0.05 mm and mechanical precision of 0.2 mm/m, thanks to its precision servo drives and integrated CNC control. It ensures clean, accurate cuts for steel, stainless steel, and aluminum, supporting both plasma arc and oxy-fuel cutting methods. The reliable performance is matched with key safety features to protect operators and equipment.

Comprehensive Connectivity and Support

With support for USB, LAN, and Network data transfer, Messer Plamill enables seamless file sharing and integration into existing workflows. The machine accommodates a broad working temperature (045C) and humidity range (<95% non-condensing), making it suitable for various industrial environments. Clients benefit from extensive online and onsite support, ensuring minimal downtime and prompt assistance when required.

FAQs of Messer Plamill Software:

Q: How does the Messer Plamill software simplify the cutting process for users?

A: The Messer Plamill software features a 15-inch touch screen and an intuitive user interface. It allows for direct import of DXF and DWG files, automatic torch height control, and fully automated gas console, streamlining complex metal sheet and plate cutting tasks for greater efficiency and accuracy.Q: What types of materials and thicknesses can be cut using this machine?

A: This system cuts mild steel, stainless steel, and aluminum with a plasma arc (up to 25 mm) or oxy-fuel (up to 100 mm) cutting method. This versatility covers a wide range of industrial applications for metal sheet and plate processing.Q: Where can data files be transferred from and how does connectivity work?

A: Data files can be transferred via USB drive, LAN, or network connections. This flexibility allows easy integration with design software and company networks, enhancing workflow efficiency for operators and managers alike.Q: What safety features ensure operator protection during machine operation?

A: Key safety features include an emergency stop function and overload protection, helping prevent accidents and equipment damage. The automatic torch height control also contributes to safe and precise operations.Q: When is onsite service support available for Messer Plamill installations?

A: Messer Plamill offers both online and onsite service support throughout India for installation, troubleshooting, and maintenance. Support ensures machines operate at peak efficiency with minimal downtime.Q: What are the benefits of the fully automated gas console and automatic height control?

A: The fully automated gas console and automatic torch height adjustment enhance cutting consistency, reduce manual mistakes, and maintain optimum cutting quality. These features boost productivity and deliver superior results for each job.Q: How does the Messer Plamill software integrate with other design tools?

A: Messer Plamill software supports importing DXF and DWG files, which are standard in CAD design platforms. This compatibility enables smooth integration into engineering and manufacturing workflows, reducing file conversion time and streamlining the production process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

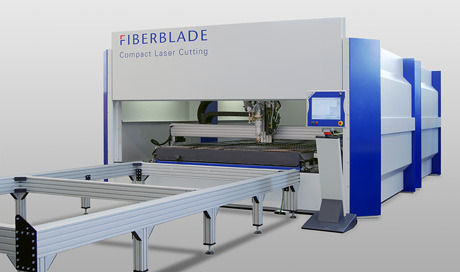

Fiber Laser Cutting Machine

Color : Other, White and Blue

Voltage : Standard industrial supply (e.g. 380V/50Hz)

Type : Other, Industrial Laser Cutting Equipment

Control System : CNC

Product Type : Fiber Laser Cutting Machine

Computerized : Yes

Automatic CNC Thermal Cutting Machine

Color : Blue

Voltage : Standard industrial voltage

Type : Other, Thermal Cutting Machine

Control System : CNC Control System

Product Type : Cutting Machine

Computerized : Yes

Z Line Filter Systems

Color : Blue

Voltage : Standard Industrial Voltage

Type : Z Line Filter Systems, Other

Control System : Manual Control

Product Type : Filtration Equipment

Computerized : No

Star Torch Kit System

Color : Other, Silver & Blue

Voltage : 220V

Type : Other, Torch Kit System

Control System : Manual Control

Product Type : Star Torch Cutting Kit

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS