Oxy Fuel Cutting

Oxy Fuel Cutting Specification

- Drive Motor

- Servo or stepper, as per configuration

- Product Type

- Industrial Metal Cutting Equipment

- General Use

- Industrial sheet and plate cutting

- Material

- Mild steel, carbon steel, alloy steel

- Type

- Oxy-Fuel Cutting Machine

- Capacity

- Varies by model, up to 2000 kg work support

- Weight (kg)

- Varies by configuration, up to 1200 kg

- Computerized

- Yes (CNC supported)

- Automatic

- Yes (fully/semi-automatic options)

- Cutting Speed

- 50 to 750 mm/min (adjustable)

- Cutting Thickness

- 5 mm to 300 mm (material dependent)

- Cutting Function

- Oxy-fuel gas cutting for steel and metals

- Cooling System

- Manual or Water Cooling (as per torch design)

- Drive Type

- Rack and pinion or AC servo drive

- Voltage

- 220V/380V/415V, 50/60Hz

- Dimension (L*W*H)

- Customized to order

- Feature

- Heavy-duty, stable construction, easy operation

- Color

- Standard industrial colors (blue, grey, yellow, etc.)

- Motor

- AC drive motor

- Mechanical Precision

- 0.5 mm/meter

- Software Detail

- Compatible with standard CNC programming software

- Cutting Method

- Oxy-fuel gas cutting with acetylene/propane/oxygen

- Control System

- Microprocessor/CNC based control panel

- Cutting Area

- Customized as per requirement

- Cutting Material

- MS, CS, SS, Alloy Steel

- Max Plate Width

- Up to 3000mm (customizable)

- Bevel Cutting

- Available as an optional feature

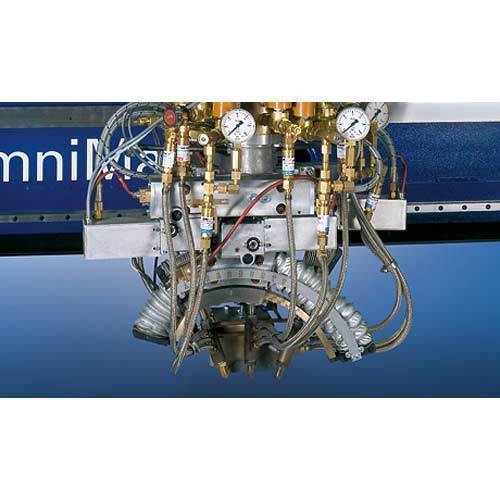

- Gas Supply

- Separate oxygen and fuel gas hoses with regulator

- Ignition System

- Manual or automatic flame ignition

- Working Environment

- 0-40°C; dust and moisture protected

- Safety Features

- Emergency stop, flame arrester, flow check valves

- Gas Pressure Required

- Oxygen: 2-5 bar; Fuel: 0.1-0.5 bar

- Max Plate Length

- Up to 12000mm (customizable)

- Guide Rail Type

- Hardened steel rails for precision

- User Interface

- LCD/Keypad or Touchscreen

- Operational Noise

- Under 80 dB

- Torch Quantity

- Single or multi-torch options

- Installation Support

- On-site training & installation provided

Oxy Fuel Cutting Trade Information

- Main Domestic Market

- All India

About Oxy Fuel Cutting

We are a Leading Service Provider for Oxy Fuel Cutting.We are a leading service provider for the Oxy Fuel Cutting.

We are engaged in providing an excellent quality service for Oxyfuel Cutting. The offered cutting service is rendered by our professionals using best grade of tools & technology. Our cutting service provides smooth, vertical planes of cut & gives best cutting. We are offering this cutting service within a given time frame to customers.

Features:

Excellent cutting quality

Low cutting speed

Metallurgical perfect surfaces

Other Details:

Good cut quality

Smooth, vertical planes of cut

Metallurgical perfect surfaces (oxidized)

Carbonizing and hardening within the area of the heat affected zone

High heat input

Limited range of material

Low cutting speed

Specifications:

Plate thickness: 1/8 inch (3 mm) up to 35 inch (900 mm)

Typical: 3 (8 inch (10 mm) up to 12 inch (300 mm)

Engineered for Industrial Precision

Our Oxy-Fuel Cutting Machine stands out with heavy-duty construction and precision-engineered hardened steel rails. Designed to handle plates up to 3000mm wide and 12000mm long, it delivers consistently accurate oxy-fuel cuts for a broad range of metals. Customizable dimensions and enhanced mechanical precision (0.5 mm/meter) ensure superior results for any industrial fabrication environment.

Advanced Safety and Operational Features

Equipped with emergency stop, flame arrester, and flow check valves, the machine prioritizes user safety during operation. The dust and moisture-resistant build, together with operational noise under 80 dB, make it suitable for demanding workshop conditions. Installation support and on-site training are provided, facilitating seamless integration and confident operation.

Flexible Control and Versatility

Choose automated or semi-automatic modes, drive types (rack and pinion, AC servo), and either manual or automatic flame ignition. The intuitive LCD/keypad or touchscreen control panel supports CNC programming, ensuring quick setup and adaptable operations. Compatible with various fuel gases, the system processes materials from 5 mm to 300 mm thick, addressing diverse cutting needs.

FAQs of Oxy Fuel Cutting:

Q: How does the Oxy-Fuel Cutting Machine achieve precise cuts on a variety of metals?

A: The machine utilizes hardened steel guide rails and a stable rack-and-pinion or AC servo drive, combined with microprocessor/CNC control for consistent precision. It is capable of cutting mild steel, carbon steel, stainless steel, and alloy steel with mechanical accuracy of 0.5 mm per meter.Q: What options are available for torch configuration and ignition methods?

A: Customers can select single or multiple torch setups based on productivity needs. Ignition can be initiated manually or through an automatic flame ignition system, enabling operational flexibility.Q: When should bevel cutting be used, and is it available with this system?

A: Bevel cutting is recommended for applications requiring angled edges, such as weld preparation. This feature is available as an optional add-on with the Oxy-Fuel Cutting Machine.Q: Where can the machine be installed, and what support is provided?

A: Designed with a protected structure against dust and moisture, the machine is suitable for industrial workshops operating between 0C and 40C. On-site installation and training are provided to ensure optimal setup and user competence.Q: What is the recommended process for starting up and safely operating the equipment?

A: Begin by ensuring gas supply hoses are connected with regulators and safety devices are engaged (flame arrester, flow check valves). Set the required gas pressures (Oxygen: 2-5 bar; Fuel: 0.1-0.5 bar), use the LCD/keypad or touchscreen interface to input the CNC cutting parameters, and proceed with manual or automatic ignition. Always engage the emergency stop if needed.Q: How does the machine benefit industrial users in terms of efficiency and safety?

A: Heavy-duty construction, customizable cutting areas, and CNC compatibility facilitate increased efficiency. Integrated safety features minimize risks, and installation/training support ensures rapid production starts, maximizing benefit and uptime for industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Mild Steel CNC Profile Cutting Machine

Type : Other, Profile Cutting Machine

General Use : Industrial Profile and Shape Cutting

Automatic : Yes

Color : Blue

Product Type : CNC Profile Cutting Machine

Feature : Other, High precision and efficiency

Bevel Head Skew Rotator Delta

Type : Other, Skew Rotator Bevel Head

General Use : CNC Plasma/Oxyfuel 3D Bevel Cutting

Automatic : Yes

Color : Other, Blue & Grey

Product Type : Bevel Cutting Head Attachment

Feature : Other, Precision Bevel Cutting, High Torque, Skew Rotator Head

Secator Cutting Machine

Type : Other, Manual and Semiautomatic options

General Use : Cutting rods, pipes, and profiles

Automatic : Other, Optional (Semiautomatic model available)

Color : Other, Industrial blue/grey

Product Type : Secator Cutting Machine

Feature : Other, Sturdy build, high accuracy, low maintenance

Messer flow meter regulator

Type : Other, Single stage with flow meter

General Use : Gas flow regulation for industrial welding/cutting

Automatic : No

Color : Other, Silver and transparent

Product Type : Flow Meter Regulator

Feature : Other, Robust body, precise flow control, clear flow tube

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS