Line Filter System

Line Filter System Specification

- Drive Motor

- 1/3 HP

- Product Type

- Line Filter System

- General Use

- Filtration of particulates/contaminants in industrial processing lines

- Material

- Metal (Steel, Aluminum) & Plastic

- Type

- Industrial Line Filter

- Capacity

- Up to 2500 m/hr Filtration

- Weight (kg)

- Approx. 30 Kg

- Computerized

- No

- Automatic

- Optional

- Control System

- Manual / Electronic

- Cooling System

- Air-Cooled, Integrated

- Drive Type

- Electric

- Voltage

- 220-240V AC

- Dimension (L*W*H)

- 1200 x 400 x 300 mm

- Feature

- High Filtration Efficiency, Durable Construction, Compact Design

- Color

- Blue / White

- Motor

- Single Phase AC Motor

- Mechanical Precision

- Filtration Accuracy Up to 5 Micron

- Mounting

- Panel Mount

- Insulation Resistance

- >= 100 M @ 500V DC

- Terminal Type

- Screw / Lug

- Insertion Loss

- >= 40 dB (150 kHz to 30 MHz)

- Frequency

- 50/60 Hz

- Enclosure Protection

- IP20/IP44 (as per model)

- Applications

- CNC machines, Medical equipment, Power supplies, Automation panels

- Operating Temperature

- -25C to +60C

- Phase

- Single Phase / Three Phase

About Line Filter System

We are a Coimbatore-based reputed company indulged in manufacturing and supplying excellent-grade Line Filter System. It is well designed and fabricated at our state-of-the-art facility under proper guidance and supervision of deft professionals. This system is designed specifically for protection of environment outside and working climate inside. Our professionals have kept in mind all industrial norms and standards while fabricating this system. Offered Line Filter System can be availed from us in models at a reasonable price range.

Features:

-

Reliable performance even in harsh conditions

-

Low maintenance requirements

-

Prolonged service life

As a family concern with a long term, consistent standpoint, we also watch out for the interests of coming generations. For this reason we always pay attention to protecting the environment and the conservation of the limited resources of our earth.

So our modern fume extraction tables and filter systems contribute to the protection of the environment outside and the working climate inside. Our process technology strives for resource conserving application of energy and consumed materials.

Messer also places great value on meeting the highest possible standards in health and safety. Our services include information and training on the handling of the gases used in our equipment.

Advanced Filtration for Industrial Applications

Our Line Filter System delivers precision filtration and superior noise suppression across a range of industrial sectors. Purpose-built for high-demand environments, it filters particulates down to 5 microns and minimizes electromagnetic interference (EMI), thereby protecting sensitive operations in CNC, medical, and power automation industries. Compact dimensions and panel-mounting simplify installation into new or existing lines.

Built for Reliability and Efficiency

Designed with robust steel, aluminum, and plastic components, the system provides durable performance in harsh industrial settings. The air-cooled design ensures longevity, while the high insertion loss (>= 40 dB) across critical frequencies guarantees stable, interference-free operations. The choice of screw or lug terminals and protection ratings up to IP44 ensure safety and flexibility.

FAQs of Line Filter System:

Q: How is the Line Filter System installed in an industrial setting?

A: The Line Filter System is designed for panel mounting using either screw or lug terminals. Its compact size (1200 x 400 x 300 mm) ensures it fits smoothly into control cabinets or processing panels. Installation should follow standard electrical safety protocols and align with equipment voltage and phase requirements.Q: What benefits does high filtration accuracy provide for industrial machinery?

A: High filtration accuracy, achieving up to 5 microns, effectively removes fine particulates and contaminants. This extends the service life of downstream components, improves operational reliability, and offers protection against electromagnetic interferenceespecially crucial in sensitive medical and automation equipment.Q: When should I consider upgrading to an automated filter system?

A: An automatic filter system is ideal if your facility handles large-scale or 24/7 operations, where constant manual monitoring is impractical. Automation increases efficiency by maintaining optimal filtration without manual intervention, supporting uninterrupted production in demanding environments.Q: Where is the Line Filter System typically used?

A: This filter is widely used in CNC machine lines, medical equipment installations, industrial power supplies, automation control panels, and electrical enclosures. Its robust design and IP20/IP44 protection make it suitable for both moderate and harsh industrial environments across India.Q: What is the process for routine maintenance on this filtration system?

A: Regular maintenance involves inspecting terminals, cleaning the exterior, and checking for particulate buildup. Ensure proper airflow for the integrated air-cooled system. Scheduled testing of insulation resistance (>= 100 M @ 500V DC) is recommended to uphold operational safety and efficiency.Q: How does the Line Filter System improve performance in automated panels?

A: By providing consistent filtration efficiency and suppressing electrical noise, the system enhances the reliability of automated panels. Its interference reduction ( 40 dB from 150 kHz to 30 MHz) facilitates precise control and reduces the risk of malfunctions in sensitive automation equipment.Q: What makes this Line Filter System suitable for different electrical configurations?

A: Support for both single-phase and three-phase operations, with manual or electronic control options, gives users flexibility to match their system requirements. Its robust construction and integrated cooling accommodate heavy-duty industrial use while maintaining filtration efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Bevel Head Skew Rotator Delta

Control System : Delta CNC Control

General Use : CNC Plasma/Oxyfuel 3D Bevel Cutting

Color : Other, Blue & Grey

Automatic : Yes

Drive Type : Other, Servo Motor Driven

Feature : Other, Precision Bevel Cutting, High Torque, Skew Rotator Head

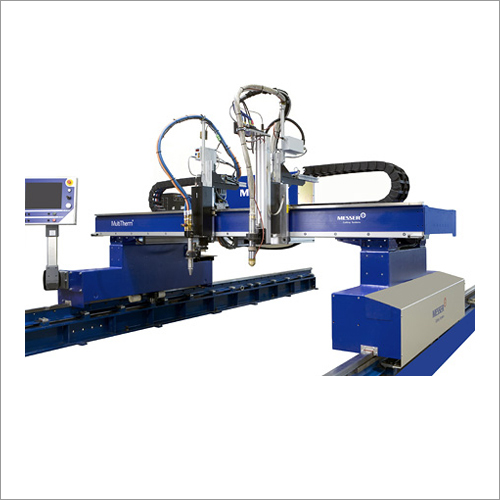

Automatic CNC Thermal Cutting Machine

Control System : CNC Control System

General Use : Industrial cutting applications

Color : Blue

Automatic : Yes

Drive Type : Other, Mechanical drive

Feature : Automated and precise cutting, Other

Cutting Tables

Control System : Userfriendly digital control panel

General Use : Fabric, paper, and leather cutting

Color : Other, Grey & Blue

Automatic : Yes

Drive Type : Other, Servo motor drive

Feature : Other, Sturdy frame, vibrationfree operation

Laser Bevel Head

Control System : Integrated CNC/PLC control panel

General Use : Laser cutting of sheet metal with angle bevels

Color : Other, Metallic/Black

Automatic : Other, Yes, with programmable angles

Drive Type : Other, Servo motor drive

Feature : Other, High precision, adjustable bevel angle, stable cutting

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS