Cutting Tables

Cutting Tables Specification

- Drive Motor

- High performance stepper/servo motor

- Product Type

- Garment and textile cutting solution

- General Use

- Fabric, paper, and leather cutting

- Material

- High-grade mild steel table, wooden surface

- Type

- Industrial Cutting Table

- Capacity

- Up to 1000 pieces/day

- Weight (kg)

- 350 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 800 mm/s

- Cutting Thickness

- Up to 25 mm

- Cutting Function

- Automatic and manual cutting modes

- Cooling System

- Integrated air cooling system

- Drive Type

- Servo motor drive

- Voltage

- 220 V / 50 Hz

- Dimension (L*W*H)

- 2100 mm x 1400 mm x 900 mm

- Feature

- Sturdy frame, vibration-free operation

- Color

- Grey & Blue

- Motor

- Servo Motor 750W

- Mechanical Precision

- 0.1 mm

- Software Detail

- Compatible with CAD/CAM software

- Cutting Method

- Rotary blade or straight knife

- Control System

- User-friendly digital control panel

- Cutting Area

- 1800 mm x 1200 mm

- Cutting Material

- Textile, foam, leather, paper

- Warranty Extension

- Available up to 3 years

- Installation Service

- Available on request

- Operating Temperature

- 10°C to 40°C

- Power Consumption

- 1.2 kW

- Table Surface Type

- Anti-static laminate

- Noise Level

- <70 dB

- Packing Type

- Export quality wooden crate

- Tabletop Thickness

- 30 mm

- Air Pressure Requirement

- 6 bar (for pneumatic models)

- Frame Material

- Powder-coated steel

- Safety Features

- Emergency stop, safety guards

- Blade Adjustment

- Manual and automatic

Cutting Tables Trade Information

- Main Domestic Market

- All India

About Cutting Tables

We are Leading Manufacturers and Suppliers of Cutting TablesIntegrate your cutting systems completely into your production by using our auxiliary equipment. Our environmental technology matches to the cutting process as well as automation and handling technology.

Our cutting tables are the ideal complement for your cutting machine. Equipped with an additional smoke extraction system, they protect the user from the harmful smoke and help to protect the environment.

High Performance and Flexibility

The table excels in speed, cutting up to 800 mm/s, and supports both manual and automatic modes for diverse production needs. Equipped with a precision servo motor drive, the system ensures accurate, vibration-free cuts across materials like textile, leather, foam, and paper.

Safety and User Convenience

Operator safety is prioritized with built-in emergency stops and protective guards. The digital control panel is intuitive, making the table easy to operate even by new users. An integrated air cooling system offers consistent, reliable performance during long shifts.

Seamless Integration and Durability

With compatibility for leading CAD/CAM software, workflows and designs can be managed digitally for efficiency. A sturdy, powder-coated frame and anti-static laminated tabletop provide longevity, while export-grade packaging ensures the table arrives in ideal condition.

FAQs of Cutting Tables:

Q: How does the anti-static laminate surface benefit the cutting process?

A: The anti-static laminate surface prevents static electricity build-up, reducing dust accumulation and material sticking. This results in smoother handling and more accurate cuts, particularly important for textiles and lightweight materials.Q: What materials and cutting methods are supported by this industrial cutting table?

A: The table is engineered to cut a range of materials, including fabric, leather, foam, and paper. It accommodates both rotary blade and straight knife cutting techniques, and users can select between manual and automatic modes based on production needs.Q: What is the installation process for the cutting table, and is service support available?

A: Installation services are available upon request and are carried out by trained professionals. The package arrives in an export-quality wooden crate to ensure protection, and complete setup assistance is provided, including connection to the required 220 V/50 Hz power supply and 6 bar air pressure for pneumatic models.Q: When should I consider extending the tables warranty, and how long is the extension available?

A: You should consider extending the warranty at the time of purchase or before the initial warranty expires. Warranty extensions are available for up to three years, offering added peace of mind and covering major components and service support.Q: Where can this cutting table be used, and what are the ideal operating conditions?

A: This cutting table is ideal for textile, garment, leather, and paper processing industries. It is suited for indoor use, within a temperature range of 10C to 40C, ensuring reliable and safe operation.Q: What are the advantages of using this computerized, servo-driven cutting table?

A: The computerized system allows seamless integration with CAD/CAM software for precise, repeatable cuts. Servo motor drives and mechanical precision of 0.1 mm ensure consistent quality, while automation increases throughput and reduces manual workload.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

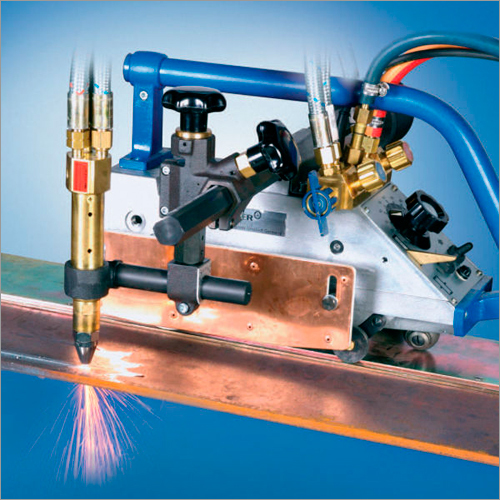

Secaator CNC Profile Cutting Machines

Weight (kg) : Approx. 50 kg

Cooling System : Other, Aircooled

Software Detail : Integrated CNC software

Cutting Function : Profile cutting, Other

Cutting Method : Gas cutting

Control System : CNC Control

Mild Steel Automatic Multitherm Eco Fiber Cutting Machine

Weight (kg) : Heavy Machine

Cooling System : Other, Air cooling

Software Detail : Custom CNC software

Cutting Function : Other, Fiber cutting

Cutting Method : Laser Cutting

Control System : CNC

Bevel Cutting Machine

Weight (kg) : 350kg

Cooling System : Other, Integrated Cooling System

Software Detail : Advanced Control Software

Cutting Function : Other, Bevel Cutting

Cutting Method : Plasma Cutting

Control System : CNC

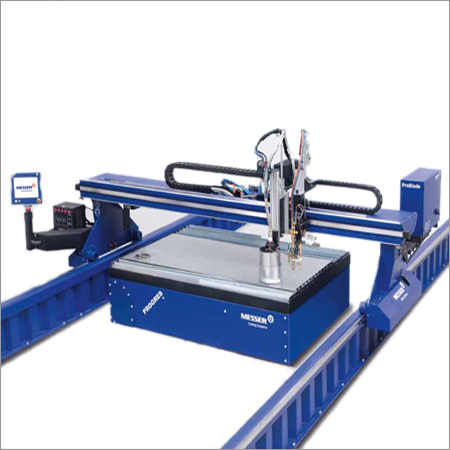

Problade - CNC Profile Cutting Machines

Weight (kg) : Heavyduty machine

Cooling System : Other, Air

Software Detail : Advanced CNC Software

Cutting Function : Other, Profile Cutting

Cutting Method : Plasma / Flame

Control System : CNC Controller

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS