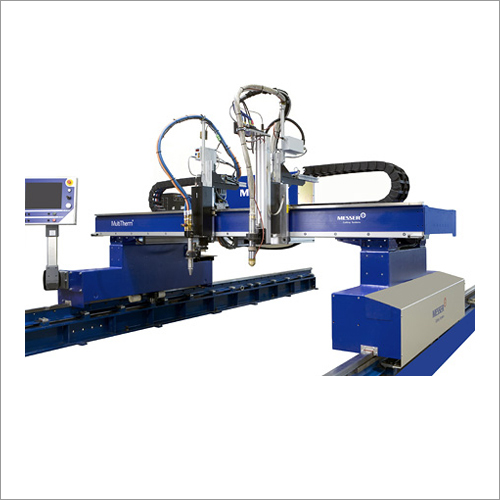

Bevel Head Skew Rotator Delta

Bevel Head Skew Rotator Delta Specification

- Drive Motor

- Servo Motor

- Product Type

- Bevel Cutting Head Attachment

- General Use

- CNC Plasma/Oxyfuel 3D Bevel Cutting

- Material

- Mild Steel, Stainless Steel, Alloy Steel, Aluminum

- Type

- Skew Rotator Bevel Head

- Capacity

- Heavy Duty Industrial

- Weight (kg)

- Approx 150 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 012000 mm/min

- Cutting Thickness

- Up to 50 mm (depending on material and torch)

- Cutting Function

- Bevel, Skew, Rotary Cutting

- Cooling System

- Water Cooling

- Drive Type

- Servo Motor Driven

- Voltage

- 380V/415V

- Dimension (L*W*H)

- 900 mm x 600 mm x 400 mm

- Feature

- Precision Bevel Cutting, High Torque, Skew Rotator Head

- Color

- Blue & Grey

- Motor

- High-Precision Servo Motor

- Mechanical Precision

- 0.05 mm

- Software Detail

- CNC Controller Supported

- Cutting Method

- Rotary Bevel Skew Cutting

- Control System

- Delta CNC Control

- Cutting Material

- Steel, SS, Aluminum, Alloy

- Cutting Area

- 1500 mm x 3000 mm

- Installation

- Bolt-on to CNC Gantry

- Communication Ports

- Ethernet/RS232/USB

- Angle Range

- 45 Degrees Skew, 52 Degrees Bevel

- Repeatability

- High repeatability with low backlash

- Protection

- Dust & Splash Proof Enclosure

- Interface

- Touchscreen Operation Panel

- Rotational Axis

- 5-Axis Capability

- Torch Type

- Plasma/Oxyfuel

- Ambient Temperature

- 5C 45C

- Power Consumption

- 2.5 kW

Bevel Head Skew Rotator Delta Trade Information

- Main Domestic Market

- All India

About Bevel Head Skew Rotator Delta

We are a leading service provider for the Bevel Cutting Plasma.With rich industry experience and knowledge, we are engaged in offering Bevel Head Skew Rotator Delta service. The tool use for cutting has Infinite C-axis rotation at a rate of 75 RPM & service is rendered by our professionals. Our cutting service includes lateral and vertical torch decoupler collision detection. We are offering this cutting service within a given time frame to customers.

Features:

Programmable arc current

Timely execution

Infinite c axis rotation

Other Details:

AC drives for high performance

Programmable arc current, arc voltage, and bevel angle.

Infinite C-axis rotation at a rate of 75 RPM, reduces cut cycle and programming time

Quick torch focal point adjustment for easy consumable changeover

Lateral and vertical torch decoupler collision detection to prevent torch damage in event of a collision

Automatic torch height control by analog arc voltage with an accuracy of +/- .006 inches

(+/- 0,15 mm) so part accuracy is maintained during bevel cutting

Resultant piece part bevel angles of +45 degrees through -45 degrees

The most successful plasma bevel cutting head ever

Compound Skew Axis System for high flexibility and productivity

No cumbersome arc segments to risk collision or inhibit the cut

Unlimited C Axis rotation

Advanced 5-Axis Precision Bevel Cutting

Achieve complex and accurate cuts with the Bevel Head Skew Rotator Deltas full 5-axis movement. The rotator allows for 45 degrees of skew and 52 degrees of bevel, making it ideal for advanced fabrication requirements on a variety of metals. High torque and low backlash ensure repeatability and edge quality, fulfilling the needs of industrial applications.

User-Friendly Touchscreen Control & Robust Protection

Operate the rotator easily through a touchscreen panel designed for hands-on production. The dust and splash-proof enclosure enhances durability, while Ethernet, RS232, and USB ports ensure connectivity to modern CNC systems. Its water cooling mechanism maintains performance throughout demanding shifts.

Versatile CNC Gantry Integration

The bolt-on installation method makes it straightforward to upgrade existing CNC gantries. Compatible with both plasma and oxyfuel torches, the rotator accommodates cutting areas up to 1500 mm x 3000 mm. Its heavy-duty build and industrial-grade servo motors provide high speed and power, supporting consistent throughput and high-quality results.

FAQs of Bevel Head Skew Rotator Delta:

Q: How is the Bevel Head Skew Rotator Delta installed onto a CNC gantry?

A: The rotator is designed for straightforward bolt-on installation to most CNC gantries, enabling easy integration with minimal downtime. Its compact dimensions and modular connections make setup convenient for both new and retrofit applications.Q: What materials and thicknesses can the rotator cut?

A: It is capable of processing mild steel, stainless steel, alloy steel, and aluminum, with cutting thicknesses up to 50 mm, depending on the torch type and material. This ensures flexibility across a wide range of industrial fabrication tasks.Q: When should I use the skew and bevel features during cutting?

A: Utilize skew and bevel cutting functions when you need precise angular cuts for weld preparation, complex edge profiles, or custom 3D components. The 5-axis head delivers optimal results in heavy-duty or intricate cutting scenarios.Q: Where can this skew rotator head be utilized?

A: Ideal for fabrication shops, shipyards, steel structure manufacturing, and any facility operating CNC plasma or oxyfuel cutting systems, especially where advanced bevel, skew, or rotary cutting is required on structural metals.Q: What is the typical process for operating the rotator?

A: Operators use the intuitive touchscreen panel to set cutting parameters, select torch type, and program bevel or skew angles. The Delta CNC controller manages all motions, with high-precision servo motors ensuring repeatability and consistent edge quality.Q: How does the dust and splash-proof enclosure benefit users?

A: This protective enclosure shields internal components from harsh working environments, reducing maintenance needs and prolonging the lifespan of the equipment in industrial settings.Q: What are the main benefits of using the Bevel Head Skew Rotator Delta?

A: Key benefits include highly accurate and repeatable 3D bevel cuts, compatibility with various cutting torches and metals, fast setup, reliable operation in tough conditions, user-friendly interface, and support for large workpieces.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in others Category

Bevel Cutting Machine

Product Type : Bevel Cutting Machine

Control System : CNC

Material : Other, Durable Alloys

General Use : Industrial Metal Cutting

Color : Black

Computerized : Yes

Automatic CNC Thermal Cutting Machine

Product Type : Cutting Machine

Control System : CNC Control System

Material : Steel frame, Other

General Use : Industrial cutting applications

Color : Blue

Computerized : Yes

Terrablade Flame Cutting Machine

Product Type : Cutting Machine

Control System : CNC

Material : Steel

General Use : Metal Fabrication

Color : Blue

Computerized : Yes

Automatic Pipe Cutting Machine

Product Type : Automatic Pipe Cutting Machine

Control System : CNC

Material : Metal, Other

General Use : Industrial pipe cutting

Color : Blue

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS