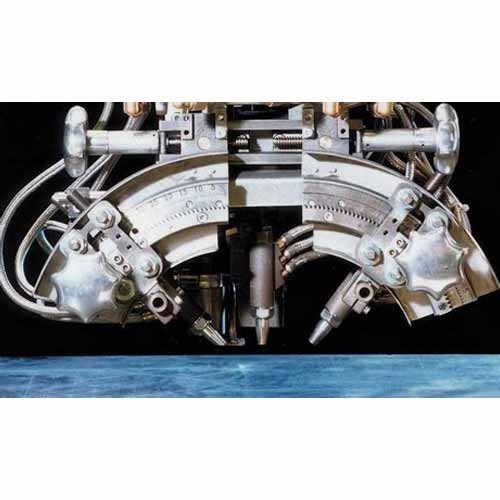

Triple Torch Unit

Triple Torch Unit Specification

- Drive Motor

- Servo Drive

- Product Type

- Triple Torch Cutting Machine

- General Use

- Plate & profile cutting in heavy industries

- Material

- Mild Steel, Stainless Steel, Aluminum

- Type

- Industrial Cutting Unit

- Capacity

- Continuous multi-line production

- Weight (kg)

- Approx. 700 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 50-800 mm/min

- Cutting Thickness

- 5-150 mm (depending on material and torch type)

- Cutting Function

- Multi-torch simultaneous or independent cutting

- Cooling System

- Water cooling / Air cooling

- Drive Type

- Servo Motor Driven

- Voltage

- 380V/415V 3 Phase, 50/60Hz

- Dimension (L*W*H)

- 3500 mm 1500 mm 1400 mm

- Feature

- High precision, triple-torch synchronized

- Color

- Industrial Blue & Yellow

- Motor

- Heavy-duty AC Servo Motor

- Mechanical Precision

- 0.2 mm/m

- Software Detail

- CNC Control Software Compatible

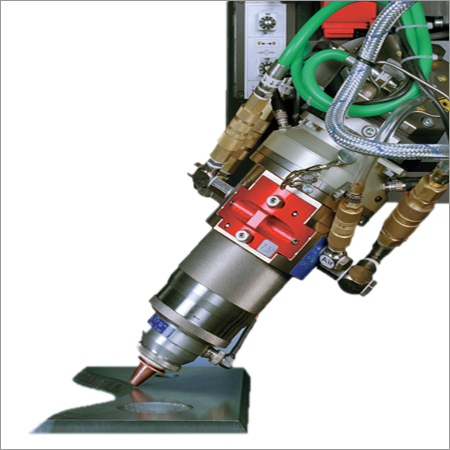

- Cutting Method

- Oxy-Fuel / Plasma (optional)

- Control System

- Digital Numeric Controller

- Cutting Area

- Customized as per requirement

- Cutting Material

- Mild steel, Stainless steel, Aluminum

About Triple Torch Unit

Providing you the best range of supertherm torch kit system and triple torch unit with effective & timely delivery.We are a leading service provider of Triple Torch Unit. The offered cutting service includes easy setting of bevel angle and lateral offset on clear scales. This cutting service doesnt need any type of rework & known for its smooth cutting operation. We are giving this cutting service to our customers at affordable rates on a given time frame to them.

Features:

Cost effective

Executed by experts

No maintenance required

Other Details:

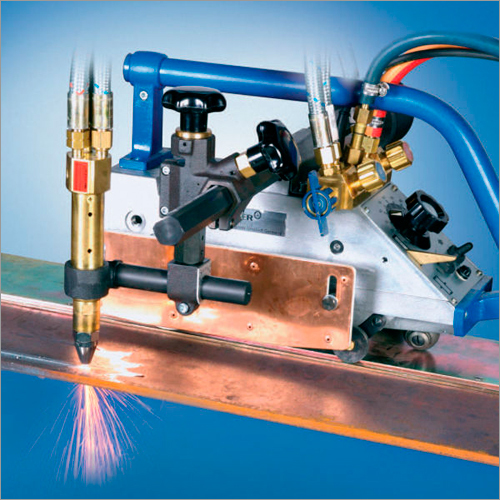

KN-Swivelling triple torch unit for straight line bevel cuts

Easy setting of bevel angle and lateral offset on clear scales

Swivelling

Precision Multi-Torch Cutting for Industrial Needs

Engineered for heavy-duty applications, this triple torch unit delivers unparalleled efficiency and accuracy for plate and profile cutting. Its unique combination of synchronized torches, customizable blade size, and mechanical adjustments supports high-volume production while maintaining a mechanical precision of 0.2 mm/m.

Advanced Operation Modes and Safety Features

With manual/automatic ignition, digital numeric controls, and a user-friendly switch mode, operation is both intuitive and flexible. Overload protection and emergency stop functions enhance operational safety, making this unit a reliable choice for intensive industrial environments.

Customization and Compatibility

Flexible by design, the cutting area and blade size are tailored according to specific requirements. Compatibility with CNC control software allows seamless integration into existing production workflows, boosting productivity for mild steel, stainless steel, or aluminum fabrication.

FAQs of Triple Torch Unit:

Q: How does the torch adjustment mechanism work on the Triple Torch Unit?

A: Each torch on the unit allows for independent vertical and lateral adjustment. This means operators can finely tune each torchs position for optimum alignment, accommodating various cutting patterns and material thicknesses.Q: What are the benefits of the dual ignition type (auto/manual) on this unit?

A: The units auto and manual ignition options provide operational flexibility. Auto ignition streamlines production for repetitive work, while manual ignition is suitable for specific setups or when extra safety control is required.Q: When is it advisable to use water cooling versus air cooling with this unit?

A: Water cooling is recommended for intensive, prolonged operations where higher heat is generated, helping maintain system stability. Air cooling is adequate for shorter or lighter-duty cycles, simplifying maintenance requirements.Q: Where can the Triple Torch Unit be deployed effectively?

A: This industrial cutting unit excels in environments such as shipyards, heavy machinery manufacturing, steel service centers, and large fabrication shops across India, offering reliable performance for various plate and profile cutting tasks.Q: What is the process for customizing the cutting area or blade size?

A: Customization involves specifying your required dimensions and desired cutting thickness when ordering. The manufacturer will tailor the machines cutting area and blade configuration to suit your operational needs, ensuring a seamless fit for your workflow.Q: How does the CNC compatibility enhance the usage of this cutting unit?

A: CNC compatibility enables automatic and highly precise multi-torch cutting, allowing operators to execute complex cuts and maximize productivity. Digital numeric control ensures accuracy and repeatability for demanding industrial tasks.Q: What are the primary safety features integrated into this model?

A: For enhanced safety, the unit features overload protection to prevent equipment damage and an emergency stop function, enabling immediate shutdown during unexpected events. These features safeguard both operators and equipment during high-capacity operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Automatic CNC Thermal Cutting Machine

Color : Metallic, Other

Material : Other, Stainless steel

Automatic : Yes

Feature : Other, Precise and reliable cutting

Drive Type : Electric drive, Other

Type : Other, Thermal cutting machine

Hypertherm Plasma Cutting Machine

Color : Blue

Material : Highgrade steel, Other

Automatic : Yes

Feature : Other, Smart Blade technology

Drive Type : Other, CNC

Type : Industrial, Other

Secaator CNC Profile Cutting Machines

Color : Blue

Material : Other, Steel assembly

Automatic : Yes

Feature : Precision cutting easy operation, Other

Drive Type : Track drive, Other

Type : Other, CNC Cutting Machine

Automatic Pipe Cutting Machine

Color : Blue

Material : Metal, Other

Automatic : Yes

Feature : Other, Automated High precision

Drive Type : Other, Linear motion

Type : Other, Automatic machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS