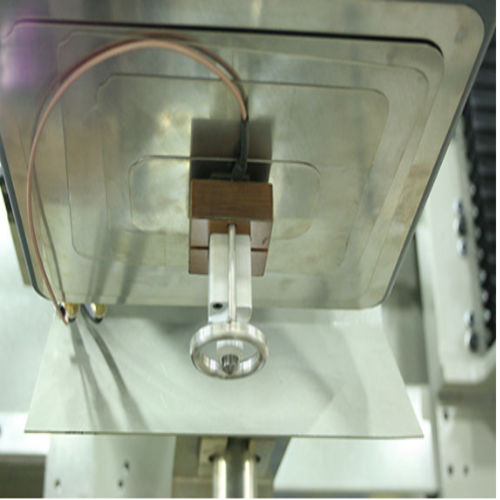

Telesis Pinstamp

Price 152000 INR/ Unit

Telesis Pinstamp Specification

- Type

- Dot Peen Marking Machine

- Material

- Mild Steel

- Capacity

- 4000/5600/6200 Markings/hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- CNC

- Cutting Speed

- Up to 100mm/sec

- Cutting Thickness

- 1 mm - 10 mm

- Cutting Function

- Marking

- Cooling System

- Air Cooling

- Drive Type

- Electric

- Weight (kg)

- 24 kg

- Dimension (L*W*H)

- 360 x 238 x 186 mm

- Color

- Grey

- Power Supply

- AC 220V 10%, 50/60Hz

- Noise Level

- 80 dB

- Marking Area

- 150 x 100 mm

- Software Compatibility

- Windows-based proprietary software

- Marking Depth

- Up to 0.5 mm (material dependent)

- Pin Material

- Tungsten Carbide

- Interface

- RS232/USB/Ethernet

- Air Pressure Requirement

- 0.30.6 MPa

- Operating Temperature

- 0C to 45C

About Telesis Pinstamp

Versatile Applications Across Industries

The Telesis Pinstamp is engineered for a multitude of uses, including marking serial numbers, logos, and component details on mild steel products. Its formidable versatility supports application areas such as automotive components, industrial equipment, metal fabrication, and aerospace parts. Widely used for traceability, product identification, and compliance markings, this dot peen machine capitalizes on CNC precision to deliver fine, permanent marks that withstand rigorous industrial environments, ensuring lasting clarity and legibility across diverse sectors.

Seamless Export and Swift Delivery Solutions

Catering to the global marketplace, the Telesis Pinstamp boasts stellar export credentials with main export markets spanning Asia, the Middle East, and Europe. Units are shipped promptly upon order confirmation, with an efficient delivery time window tailored for international clients. Sale price guidance and exchange services are available, and dispatch is managed from the designated FOB port in India, ensuring a streamlined, reliable procurement experience for distributors and end-users worldwide.

FAQ's of Telesis Pinstamp:

Q: How does the Telesis Pinstamp operate for marking different materials?

A: The Telesis Pinstamp utilizes a sturdy tungsten carbide pin, automatically controlled via a CNC system, to create high-resolution, permanent marks up to 0.5 mm deep on a range of material surfaces. The marking depth depends on the material's hardness and thickness.Q: What are the advantages of its computerized, automatic system?

A: The computerized, automatic (CNC) system ensures precise, repeatable, and rapid marking-up to 6200 markings per hour-minimizing manual errors and maximizing throughput, especially for large production runs.Q: When should you use the Telesis Pinstamp for product identification?

A: This machine is ideal when permanent, clear, and traceable markings are needed for compliance, quality assurance, or inventory tracking in industrial environments, particularly on metal components.Q: Where can the Telesis Pinstamp machine be installed?

A: Featuring a compact design with dimensions of 360 x 238 x 186 mm and air cooling, the Pinstamp can be installed in production floors, workshops, or dedicated marking stations wherever controlled industrial marking is essential.Q: What benefits does its multi-interface connectivity offer users?

A: Users can access and control the Pinstamp via RS232, USB, or Ethernet, allowing seamless integration into existing manufacturing setups and facilitating straightforward data exchanges with Windows-based software systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Marking Category

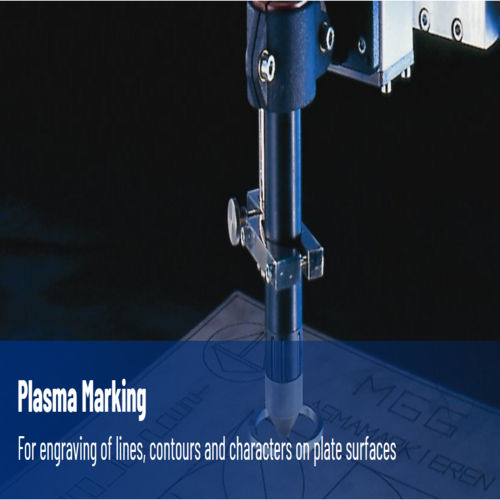

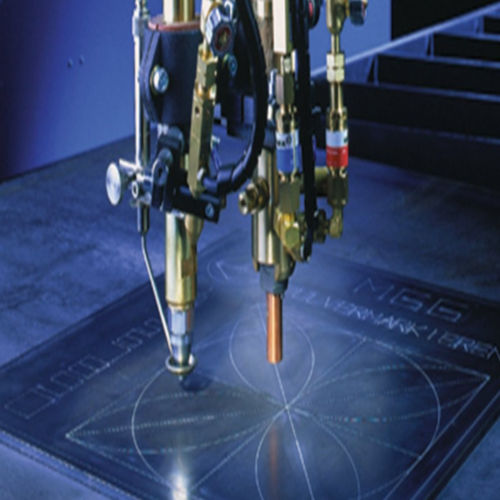

Plasma Marking

Price 185000 INR / Unit

Minimum Order Quantity : 01 Unit

Drive Type : Electric

Cooling System : Other, Air Cooled

Control System : Other, CNC

Weight (kg) : 450 kg

Powder Marking

Price 190000 INR / Unit

Minimum Order Quantity : 01 Unit

Drive Type : Electric

Cooling System : Air Cooling

Control System : PLC Control

Weight (kg) : 650

Air Scribe Marking

Price 155000 INR / Unit

Minimum Order Quantity : 01 Unit

Drive Type : Pneumatic

Cooling System : Other, Air Cooled

Control System : Other, Push Button / Trigger Operation

Weight (kg) : Approx. 0.2 0.3 kg

Pneumatic Punch Marker

Price 250000 INR / Unit

Minimum Order Quantity : 01 Unit

Drive Type : Pneumatic

Cooling System : Other, Air Cooled

Control System : Other, Pneumatic & Electronic

Weight (kg) : Approx. 18 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS