Pneumatic Punch Marker

Price 250000 INR/ Unit

Pneumatic Punch Marker Specification

- Type

- Pneumatic Punch Marker

- Material

- Stainless Steel

- Capacity

- Up to 2.0 mm marking depth

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Control System

- Pneumatic & Electronic

- Cutting Speed

- 100-200 mm/s

- Cutting Function

- Marking Only

- Cooling System

- Air Cooled

- Drive Type

- Pneumatic

- Weight (kg)

- Approx. 18 kg

- Dimension (L*W*H)

- 290 x 210 x 340 mm

- Color

- Blue/Silver

- Operating Pressure

- 0.3-0.6 MPa

- Input Mode

- Touch screen or Keypad

- Voltage

- AC 220V, 50/60Hz

- Noise Level

- < 75 dB

- Marking Speed

- 30 characters/min

- Applicable Materials

- Metal, Steel, Aluminum, Brass, Hard Plastics

- Marking Area

- 80 x 40 mm

About Pneumatic Punch Marker

Specific and General Application Advantages

The Pneumatic Punch Marker is quintessential for both specialized and general marking needs. Ideal for application on the surface of metals, steel, aluminum, brass, and hard plastics, it offers precise identification marks for quality control, inventory, or branding purposes. Its semi-automatic operation and air-cooled system guarantee competitive advantages such as swift setup, minimal noise, and deep, permanent markings, making it a compelling choice for industrial marking across multiple sectors.

Exports, Domestic Market, and Packaging Details

Our Pneumatic Punch Marker reaches a broad export market, with strong demand in regions valuing robust engineering and precision. The main domestic market includes manufacturers and service providers throughout India. Packaging ensures secure delivery, with every unit carefully boxed to protect critical components. The list price reflects comprehensive value, while markdowns and sale prices are periodically available. Products are thoroughly tested and promptly dispatched to meet fast-paced industrial requirements.

FAQ's of Pneumatic Punch Marker:

Q: How does the Pneumatic Punch Marker achieve cost-effective marking?

A: The Pneumatic Punch Marker combines pneumatic and electronic controls with air-cooled technology, delivering reliable, high-speed marking with low operational costs. Its durable stainless steel construction and automated features reduce maintenance and labor expenses, further contributing to instant savings.Q: What materials can be marked using this Pneumatic Punch Marker?

A: This marker is designed for use on a wide range of materials, including metal, steel, aluminum, brass, and hard plastics, ensuring flexibility across various industrial marking applications.Q: When should I choose a pneumatic marking system over traditional methods?

A: Choose a pneumatic marking system when you need durable, deep, and high-speed markings, especially on hard materials. This ensures permanent results suitable for serial numbers, batch codes, or part identification in industrial settings.Q: Where is this Pneumatic Punch Marker most commonly used?

A: It is predominantly utilized in manufacturing plants, steel workshops, automotive facilities, and any industry where reliable, high-precision marking is critical for traceability and quality assurance.Q: What is the process for operating the marker using the computerized system?

A: Users can input marking instructions via the touch screen or keypad. The pneumatic and electronic control system automates the marking process, with an operator guiding material placement and overseeing quality during each run.Q: What benefit does the semi-automatic grade offer?

A: Semi-automatic operation blends automation for efficiency with manual oversight, ensuring both speed and control. This feature allows for tailored adjustments based on different marking tasks and materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Marking Category

Powder Marking

Price 190000 INR / Unit

Minimum Order Quantity : 01 Unit

Dimension (L*W*H) : 1700 x 1000 x 1200 mm

Capacity : Customizable

Cooling System : Air Cooling

Weight (kg) : 650

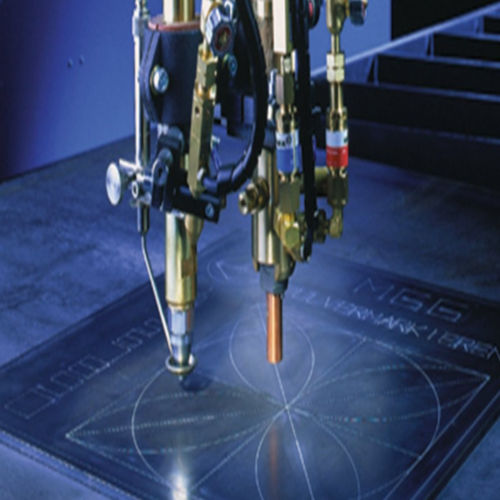

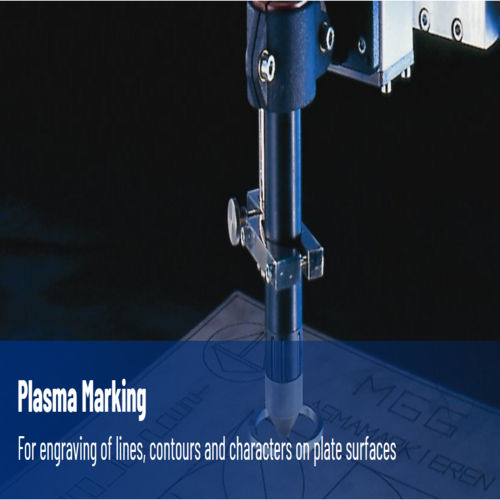

Plasma Marking

Price 185000 INR / Unit

Minimum Order Quantity : 01 Unit

Dimension (L*W*H) : 1820 x 1524 x 800 mm

Capacity : As per requirement

Cooling System : Other, Air Cooled

Weight (kg) : 450 kg

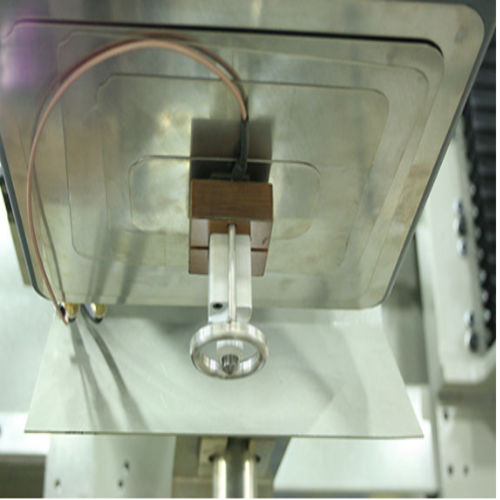

Telesis Pinstamp

Price 152000 INR / Unit

Minimum Order Quantity : 01 Unit

Dimension (L*W*H) : 360 x 238 x 186 mm

Capacity : 4000/5600/6200 Markings/hour

Cooling System : Air Cooling

Weight (kg) : 24 kg

Air Scribe Marking

Price 155000 INR / Unit

Minimum Order Quantity : 01 Unit

Dimension (L*W*H) : Approx. 165 mm x 17 mm x 25 mm

Capacity : High Frequency Scribing

Cooling System : Other, Air Cooled

Weight (kg) : Approx. 0.2 0.3 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS