Pressure Regulators

Pressure Regulators Specification

- Automation Grade

- Manual

- Application

- Gas Flow Control, Industrial, Medical, Welding, Laboratories

- Equipment Type

- Pressure Regulator

- Power Source

- Manual / Pneumatic

- Diameter

- Standard / Customized

- Type

- Pressure Regulator

- Condition

- New

- Motor Type

- Manual

- Material

- Brass / Stainless Steel

- Dimensions

- Standard / Custom

- Rated Capacity

- Varies by Model

- Mounting Type

- Panel / Cylinder / Inline

- Body Finish

- Chrome Plated / Nickel Plated / Polished

- Leakage

- Leak Proof (Tested)

- Compatible Gases

- Oxygen, Nitrogen, Argon, CO2, Hydrogen, Air, Acetylene and more

- Number of Gauges

- 1 or 2 gauge option

- Seal Material

- NBR / EPDM / PTFE

- Weight

- 0.5 kg to 2.5 kg (approx, model dependent)

- Display

- Analog Gauge

- Temperature Range

- -20°C to +60°C (may vary by model)

- Operating Pressure Range

- Up to 250 bar (varies by model)

- Flow Rate

- 0.5 to 50 m³/hr (depending on regulator type)

- Inlet Connection

- BSP/NPT/Nut Type as per requirement

- Outlet Connection

- BSP/NPT as per standard

- Regulator Stage

- Single Stage / Double Stage

Pressure Regulators Trade Information

- Main Domestic Market

- All India

About Pressure Regulators

Established in 2008, we are a Tamil Nadu-based company engaged in manufacturing and supplying excellent quality Cylinder Pressure Regulators. These are designed and fabricated by our specialists who have years of experience in this field. These regulators are widely used in various engineering industries for calculating the pressure inside a system. They are easy to operate and requires negligible maintenance during its entire lifetime. We offer Cylinder Pressure Regulators in different models and technical specifications as per requirements.

Features:

-

Ergonomic operation

-

Precise and accurate readings

-

Sturdy build quality

Versions:

Single stage and two-stage

Inlet pressures up to 200 bar and 300 bar

Special versions for high flow rates

Available with connections to DIN, CEN, BS and CGA

Advantages:

BAM registered

Extreme safety thanks to central filter

Double secured outlet pressure limitation

Ergonomic operation and high operating comfort thanks to specially designed operating knobs

Scope of supply:

Pressure regulator for Oxygen, Acetylene, Propane, MAPP, Hydrogen, Methane, Coal gas, Forming gas Argon and other inert gasses, mixed gas, CO2, Nitrogen, Compressed Air, Test gas, Caron Monoxide, Nitrous oxide

Accessories, consumable parts

Versatile Gas Compatibility

Designed to work seamlessly with a variety of gases including oxygen, nitrogen, argon, CO2, hydrogen, air, and acetylene, these pressure regulators are ideal for diverse operational environments. Whether managing specialty gases in laboratories or supplying essential flows in medical facilities, users can rely on robust compatibility and secure operation.

Durable Construction and Finish

Manufactured from high-grade brass or stainless steel, and finished with chrome, nickel, or polished coatings, these regulators offer enhanced corrosion resistance and aesthetic appeal. Their durable design ensures long-lasting performance even in demanding industrial applications.

Flexible Configuration Options

Available in a range of connection types (BSP/NPT/Nut) and mounting options (panel, cylinder, inline), our regulators support standard or custom dimensions, single or double gauge setups, and both single and double stage regulation. This flexibility allows seamless integration into existing or new gas delivery systems.

FAQs of Pressure Regulators:

Q: How do I select the right pressure regulator model for my application?

A: To choose the right model, consider your required operating pressure (up to 250 bar), type of gas (oxygen, nitrogen, argon, etc.), flow rate needs (0.5 to 50 m/hr), and desired features such as single or double stage regulation. Also factor in your preferred inlet/outlet connections and mounting style.Q: What are the available mounting options for these pressure regulators?

A: Our pressure regulators can be mounted on panels, cylinders, or inline within piping systems, depending on your installation needs. Custom mounting solutions are also available upon request to fit unique applications.Q: Where can these pressure regulators be used?

A: These regulators are suitable for industrial gas handling, medical gas systems, laboratory equipment, welding setups, and other gas flow control environments. Their compatibility with multiple gases makes them versatile for various industries.Q: What materials are used in the body and seals of the regulators?

A: Regulators are constructed from brass or stainless steel and finished with chrome plating, nickel plating, or a polished surface. Seal materials include NBR, EPDM, or PTFE, selected for optimal chemical resistance and durability.Q: How is leakage prevented in these pressure regulators?

A: Each unit is rigorously leak-tested to ensure it is completely leak-proof. The use of premium seal materials and precise manufacturing standards maintains reliable gas containment during operation.Q: What benefits do single and double stage regulators offer?

A: Single stage regulators provide fast pressure reduction for general applications, while double stage regulators deliver more consistent outlet pressureideal for processes demanding precision control despite inlet pressure fluctuations.Q: How can I obtain custom configurations or dimensions for specific requirements?

A: Custom configurations, including dimensions and fitting types, can be provided upon request. Please contact our technical team or authorized distributors in India to discuss your unique application needs and receive tailored solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oxyfuel Technology Category

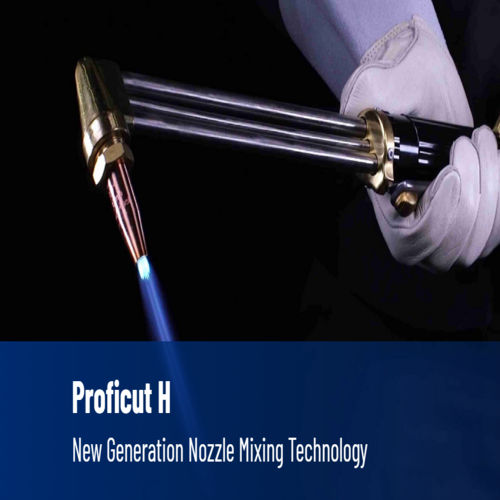

Cutting Torch - ProfiCut H

Price 1500000 INR / Unit

Minimum Order Quantity : 01 Unit

Automation Grade : Manual

Application : Heavy Duty Metal Cutting

Condition : New

Type : ProfiCut H

Cutting Torch - StableCut

Automation Grade : Manual

Application : Metal Cutting

Condition : New

Type : Cutting Torch

Safety Devices (Flashback Arrestor)

Price 1582000 INR / Unit

Minimum Order Quantity : 01 Unit

Automation Grade : Manual

Application : Welding Safety

Condition : New

Type : Flashback Arrestor

Cutting Torch - StarCut

Automation Grade : Manual

Application : Metal Cutting, Steel Fabrication, Industrial Use

Condition : New

Type : Cutting Torch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS