Cutting Torch - StarCut

Cutting Torch - StarCut Specification

- Application

- Metal Cutting, Steel Fabrication, Industrial Use

- Welding

- No

- Diameter

- Compatible With Multiple Nozzle Diameters

- Automation Grade

- Manual

- Power Source

- Oxy-Acetylene or Oxy-LPG Fuel Gases

- Equipment Type

- Gas Cutting Torch

- Type

- Cutting Torch

- Condition

- New

- Motor Type

- Manual

- Material

- Forged Brass Body, Stainless Steel Tube

- Power

- Manual, Not Electrical

- Dimensions

- Approx. 470 mm Length

- Rated Capacity

- Up to 300 mm (Steel Cutting Capacity)

- Handle Type

- Ergonomic, Anti-Slip

- Torch Body

- Heavy Duty, Robust Construction

- Compatible Gases

- Acetylene, LPG, Propane

- Model

- StarCut

- Cutting Capacity

- Up to 300 mm (with appropriate nozzle)

- Mixing Principle

- Nozzle Mixing Type

- Standard Accessories

- Supplied With Tip and Nozzle

- Weight

- Approx. 1.2 kg

- Nozzle Type

- Positive Pressure

About Cutting Torch - StarCut

Ever since our establishment in 2008, we are indulged in manufacturing and supplying excellent quality Plasma Cutting Torches. These are widely used in metalworking industries for cutting metals into desired sizes and dimensions. This torch blows an inert gas at high speeds and through an electrical arc. As a result, some of the gas is turned into plasma thereby providing means for cutting. Offered Plasma Cutting Torches are well examined and tested on defined quality parameters prior to dispatch.

Features:

-

Clean and efficient cutting

-

Sturdy build quality

-

Negligible maintenance requirements

Leveraging on our sophisticated infrastructural facility, we are offering Triple Torch Unit D/KS service. The technology use for this service has automatic infinitely rotating & offers straight cuts up to 150 mm plate thickness. Our service provides best results keeping in mind all the requirements of customers. We are offering this service within a given time frame to customers.

Features:

Cuts up to 80 mm thick plate

Include lateral adjustment of tool

Reliable cutting

Other Details:

Automatic infinitely rotating

For V, X, Y and K cuts

Bevel cuts up to 80 mm plate thickness

Straight cuts up to 150 mm plate thickness

Angle adjustment manual 15 - 60

Lateral adjustment 50 mm

Stroke 250 mm

Robust Construction for Industrial Applications

Designed to withstand demanding environments, the StarCut Cutting Torch features a forged brass body and a stainless steel tube for long-lasting performance. Its heavy-duty build ensures reliable operation in steel fabrication and various metal cutting industries.

Versatile Gas Compatibility and Nozzle Options

StarCut supports multiple gases, including acetylene, LPG, and propane, and is compatible with various nozzle diameters. This versatility allows users to adapt the torch for different cutting requirements, providing exceptional flexibility in industrial settings.

User-Focused Ergonomics and Safety

The ergonomic, anti-slip handle delivers a comfortable grip, reducing operator fatigue during extended use. StarCuts nozzle mixing technology ensures precise flame control, while the manual, non-electrical operation adds an extra layer of safety.

FAQs of Cutting Torch - StarCut:

Q: How does the StarCut Cutting Torch operate for different gas types?

A: The StarCut Cutting Torch is compatible with oxy-acetylene and oxy-LPG (propane) fuel gases. Simply attach the suitable gas hoses, fit the correct tip and nozzle for your application, and adjust the gas flow for stable operation. The nozzle mixing principle ensures a consistent, controlled flame regardless of the chosen fuel.Q: What materials and thicknesses can the StarCut Cutting Torch handle?

A: The StarCut torch is primarily designed for metal cutting and can handle steel plates up to 300 mm thick, provided the correct nozzle is used. Its robust construction makes it ideal for heavy-duty steel fabrication and industrial metal cutting projects.Q: When should I replace the tip or nozzle on the StarCut Cutting Torch?

A: Tips or nozzles should be replaced if you notice uneven flame patterns, decreased cutting efficiency, or physical damage. Regular inspection and maintenance help ensure optimal performance and prolong the lifespan of the torch.Q: Where can the StarCut Cutting Torch be used effectively?

A: This cutting torch is fit for a variety of settings, including metal workshops, steel fabrication units, and industrial manufacturing plants throughout India. Its design and materials allow it to operate under tough industrial conditions.Q: What is the process for setting up and starting the StarCut Cutting Torch?

A: To set up, securely connect the torch to oxygen and fuel gas cylinders, attach the supplied tip or nozzle, and check for gas leaks. Follow standard safety procedures, then open the valves and ignite the torch according to manufacturer guidelines for safe and efficient metal cutting.Q: What are the main benefits of using the StarCut Cutting Torch?

A: Key benefits include high cutting capacity (up to 300 mm), compatibility with multiple gases, a durable and ergonomic design, and ease of manual operation. These features make it suitable for various industrial metal cutting tasks, ensuring efficiency and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oxyfuel Technology Category

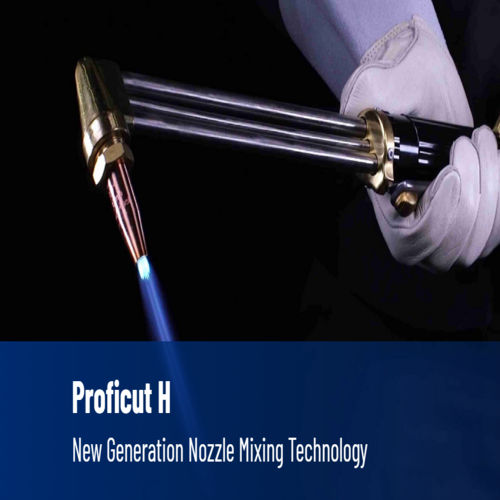

Cutting Torch - ProfiCut H

Price 1500000 INR / Unit

Minimum Order Quantity : 01 Unit

Type : ProfiCut H

Condition : New

Application : Heavy Duty Metal Cutting

Automation Grade : Manual

Safety Devices (Flashback Arrestor)

Price 1582000 INR / Unit

Minimum Order Quantity : 01 Unit

Type : Flashback Arrestor

Condition : New

Application : Welding Safety

Automation Grade : Manual

Pressure Regulators

Type : Pressure Regulator

Condition : New

Application : Gas Flow Control, Industrial, Medical, Welding, Laboratories

Automation Grade : Manual

Overview Oxyfuel Technology

Price 175000 INR / Unit

Minimum Order Quantity : 01 Unit

Type : Oxyfuel

Condition : New

Application : Metal Cutting

Automation Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS