Metal Laser Cutting

Metal Laser Cutting Specification

- Drive Motor

- AC Servo Motor

- Product Type

- Metal Laser Cutter

- General Use

- Metal Sheet and Plate Cutting

- Material

- Mild Steel, Stainless Steel, Aluminum, Brass

- Type

- Laser Cutting Machine

- Capacity

- 600 W to 4000 W (laser power range)

- Weight (kg)

- 2500 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 0-30 m/min (material dependent)

- Cutting Thickness

- 0.5 mm to 16 mm (varies by material type)

- Cutting Function

- High Precision Laser Cutting

- Cooling System

- Water Cooling

- Drive Type

- Servo Motor Drive

- Voltage

- 220V/380V

- Dimension (L*W*H)

- 4800 mm x 2300 mm x 1700 mm

- Feature

- Rustproof, Durable Frame, High Speed, Precise Finish

- Color

- Multicolor (Standard Industrial)

- Motor

- High Precision Servo Motor

- Mechanical Precision

- 0.01 mm

- Software Detail

- CNC Control Software

- Cutting Method

- Laser Beam

- Control System

- CNC

- Cutting Area

- 1500 mm x 3000 mm

- Cutting Material

- Metal Sheets: Steel, Aluminum, Copper, Brass

- Repeatability

- 0.01 mm

- BladeSize

- No blade, Fiber Laser Source

- Service Life

- >100,000 Hours (laser source)

- Interface

- USB / LAN

- Laser Source Type

- Fiber Laser

- Application

- Industrial Manufacturing, Sheet Metal Fabrication

- Laser Power

- 1000W / 1500W / 2000W / 3000W (optional)

- Max Sheet Size

- 3000 mm x 1500 mm

- Focusing System

- Automatic

- Supported File Formats

- DXF, PLT, AI, CAD

- Safety Features

- Emergency Stop, Safety Cover

- Table Structure

- Heavy Duty Welded Frame

- Power Supply

- AC 380V 50/60Hz

- Operating Temperature

- 5C to 40C

- Positioning Accuracy

- 0.01 mm

- Relative Humidity

- 95%

- Assistant Gas

- Oxygen, Nitrogen, Air

Metal Laser Cutting Trade Information

- Main Domestic Market

- All India

About Metal Laser Cutting

We are a leading service provider for the Laser Cutting.We introduce ourselves as an eminent organization for offering exceptional service of Straight Cutting Laser. Depending upon the thickness, cut quality and cutting speed we offer you a cutting service which is carried out by skilled professionals. Our cutting service is well known in the market due to its economic nature & smooth execution. Customers can avail this cutting service from us as per their need at their budgetary constraints.

Other Details:

Flexible cutting

Rendered by experts

Reliable service

High Precision Fiber Laser Cutting

This machine achieves outstanding accuracy with a positioning tolerance and repeatability of 0.01 mm, making it ideal for jobs requiring meticulous detail and consistent results. Automatic focusing and servo motor drives further enhance its ability to cut complex shapes at high speed.

Versatile Material Handling and Applications

Designed for a range of metals such as steel, aluminum, copper, and brass, the fiber laser cutter manages sheet sizes up to 3000 mm x 1500 mm. With adjustable cutting power (1000W to 3000W), it caters to diverse industrial, manufacturing, and fabrication tasks.

Advanced Safety and User Experience

Equipped with emergency stops, safety covers, and efficient cooling, the machine ensures operational safety and stability. Its intuitive CNC software, USB/LAN interfaces, and rustproof construction simplify use and maintenance, maximizing uptime in demanding environments.

FAQs of Metal Laser Cutting:

Q: How does the fiber laser cutting process work for metal sheets?

A: Fiber laser cutting uses a concentrated laser beam to melt or vaporize metal, guided by CNC controls for precise, automated movement. This method produces high-quality edges for sheet metals like steel, aluminum, and brass with little to no post-processing needed.Q: What types of files are compatible with this metal laser cutting machine?

A: The machine accepts DXF, PLT, AI, and CAD file formats, ensuring seamless integration with most popular design and drafting software for easy job setup and control.Q: When should I choose different laser power options (1000W/1500W/2000W/3000W)?

A: Select higher power (2000W/3000W) for thicker or harder metals that require deeper penetration or faster cutting. For thinner sheets or lower workloads, 1000W to 1500W is sufficient and more energy-efficient.Q: Where can this fiber laser cutter be used effectively?

A: This machine is best suited for industrial manufacturing facilities, sheet metal fabrication workshops, and service providers needing to process large or intricate metal parts with high speed and accuracy.Q: What are the primary benefits of using a fiber laser source for metal cutting?

A: Fiber laser sources offer longevity (>100,000 hours), high cutting speed, minimal maintenance, and superior precision. They provide clean, oxidation-free cuts and are highly energy-efficient compared to traditional methods.Q: How do the safety features of the machine contribute to operator protection?

A: It includes emergency stop functions and a safety cover to prevent exposure to the laser beam and moving components, ensuring a secure working environment for operators during all stages of the cutting process.Q: What steps are involved in preparing and running a cutting job?

A: Begin by loading your compatible design file via USB or LAN, selecting material type and thickness, choosing the assistant gas, and configuring CNC parameters. The automatic focusing system, water cooling, and servo-driven setup then optimize performance and precision throughout the job.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Laser Bevel Head

Feature : Other, High precision, adjustable bevel angle, stable cutting

Product Type : Laser Cutting Machine Head

Control System : Integrated CNC/PLC control panel

Color : Other, Metallic/Black

General Use : Laser cutting of sheet metal with angle bevels

Automatic : Other, Yes, with programmable angles

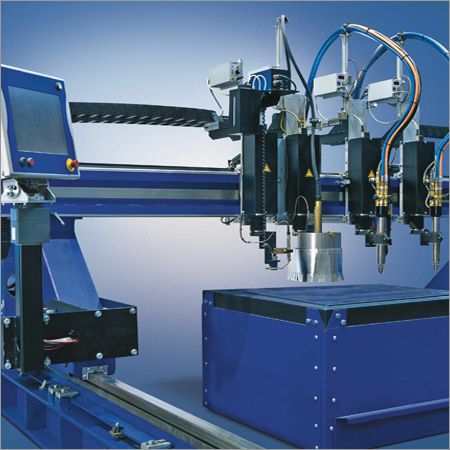

Eco CNC Thermal Cutting Machine

Feature : Other, Highly efficient, low operating cost, robust construction

Product Type : Industrial Machinery

Control System : Digital CNC

Color : Other, Blue & Gray

General Use : Sheet metal cutting

Automatic : Yes

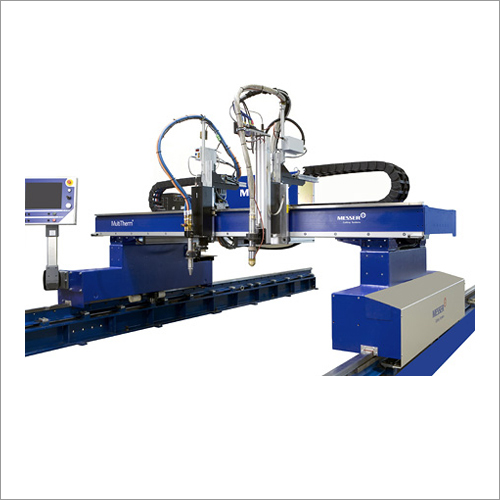

CT14 Automatic CNC Thermal Cutting Machine

Feature : Other

Product Type : Cutting Machine

Control System : CNC Control System

Color : Blue

General Use : Industrial cutting applications

Automatic : Yes

Automatic Straight Oxy Fuel Cutting

Feature : Other

Product Type : Straight Oxy Fuel Cutting

Control System : CNC Control

Color : Blue

General Use : Metal fabrication and industrial cutting

Automatic : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS