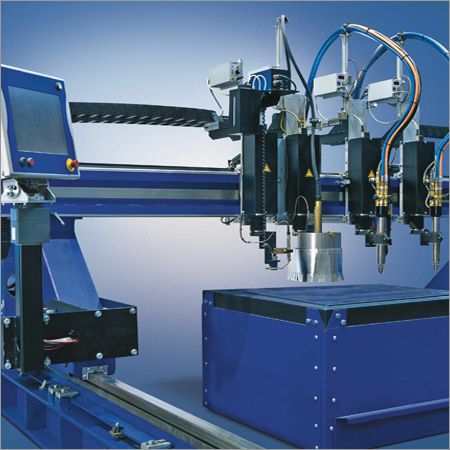

Eco CNC Thermal Cutting Machine

Eco CNC Thermal Cutting Machine Specification

- Drive Motor

- Dual side AC servo

- Product Type

- Industrial Machinery

- General Use

- Sheet metal cutting

- Material

- Mild steel, stainless steel, aluminum

- Type

- Thermal Cutting Machine

- Capacity

- Heavy duty continuous operation

- Weight (kg)

- 1050

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 6000 mm/min (max)

- Cutting Thickness

- Up to 150 mm (depending on cutting method)

- Cutting Function

- Plasma and Flame cutting

- Cooling System

- Air cooled

- Drive Type

- Dual drive

- Voltage

- 380 V / 50 Hz

- Dimension (L*W*H)

- 4200 mm x 2300 mm x 1600 mm

- Feature

- Highly efficient, low operating cost, robust construction

- Color

- Blue & Gray

- Motor

- AC Servo motors

- Mechanical Precision

- 0.5 mm

- Software Detail

- Eco CNC Controller

- Cutting Method

- CNC guided plasma/flame

- Control System

- Digital CNC

- Cutting Area

- 1500 mm x 3000 mm

- Cutting Material

- Mild steel, stainless steel, aluminum

- Dust Extraction

- Optional

- Operating Temperature

- 0°C to 45°C

- Programming Format

- G-code compatible

- Torch Height Control

- Automatic

- File Transfer

- USB and Ethernet

- Input Gas

- Oxygen/Propane/Compressed Air

- Guide System

- Linear guides

- Supported Drawing Format

- DXF, DWG

- Safety Feature

- Emergency stop switch

- Installation

- Floor mounting

- Display

- 7-inch LCD Touchscreen

- Rail Length

- 3500 mm

- Repeatability

- ±0.3 mm

- Power Consumption

- 6 kW (max)

About Eco CNC Thermal Cutting Machine

Backed by our diligent employees and rich industry experience, we have managed to become one of the leading manufacturers and suppliers of Eco CNC Thermal Cutting Machine. This machine uses a combination of fuel gases and oxygen to cut metals with precision. The cutting process begins by using a torch to heat a metal to its kindling temperature and then a stream of oxygen is trained onto the metal. Heat generated during the formation of metal oxide assists in cutting metals. Offered Eco CNC Thermal Cutting Machine can be availed from us in different models and specifications as per requirements.

Features:

-

Highly efficient and precise cutting

-

Easy to operate and maintain

-

Rugged construction

Advanced Precision and Automation

This cutting-edge machine features automatic torch height control, computerized dual drive, and linear guide systems for remarkable cutting precision (0.3 mm repeatability). The integration of AC servo motors and a digital CNC system ensures consistently smooth motion, allowing for intricate designs and reproducibility batch after batch, supporting high-volume manufacturing processes.

User-Friendly Operation and Connectivity

Equipped with a 7-inch LCD touchscreen and G-code compatible Eco CNC Controller, this machine streamlines operation for both seasoned professionals and new users. File uploads are effortless using USB or Ethernet, while supported DXF and DWG files provide extensive compatibility. Installation is floor-mounted and straightforward, facilitating seamless incorporation into your production workflow.

Robust Construction for Heavy-Duty Use

Engineered with durable materials and a heavy chassis, this machine can withstand the rigors of continuous industrial operation. Its robust build, air-cooled system, and maximum 6 kW power consumption guarantee longevity and cost-effective performance, even under demanding conditions. The emergency stop feature and optional dust extraction further enhance workplace safety.

FAQs of Eco CNC Thermal Cutting Machine:

Q: How does the Eco CNC Thermal Cutting Machine ensure precise and repeatable cutting results?

A: Precision is achieved through dual AC servo motors, linear guide rails, and automatic torch height control. The machine boasts a repeatability of 0.3 mm and mechanical precision of 0.5 mm, making it highly reliable for detailed sheet metal fabrication.Q: What types of materials and thicknesses can be processed with this machine?

A: The Eco CNC supports cutting mild steel, stainless steel, and aluminum sheets, with cutting thicknesses up to 150 mm, depending on whether plasma or flame cutting is used.Q: Where can this machine be installed and what is required for installation?

A: Designed for floor mounting, the machine is suitable for industrial facilities with standard 380 V/50 Hz power supply. Its robust construction and integrated safety features make it ideal for factories and sheet metal workshops across India.Q: What are the benefits of automatic features such as torch height control and digital CNC operation?

A: Automatic torch height control maintains optimal cutting distance, enhancing cut quality and reducing manual adjustments. The Eco CNC Controller and digital CNC interface streamline setup and operation, improving productivity and minimizing operator training time.Q: How are cutting programs and drawings transferred to the machine?

A: Programs and design files (DXF, DWG, or G-code format) can be easily uploaded through USB or Ethernet connections, enabling flexible and efficient workflow integration into your existing digital infrastructure.Q: When is dust extraction recommended and is it included?

A: Dust extraction is recommended if working extensively with materials that generate particulate or when maintaining a clean environment is essential. This feature is available as an optional addition to the standard machine package.Q: What sets this thermal cutting machine apart for heavy-duty industrial use?

A: Its robust build, 6 kW maximum power consumption, heavy-duty construction, and ability for continuous operation make it well-suited for demanding industrial settings. These characteristics ensure minimal downtime and a low operating cost over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Aluminium Profile Cutting Machine

Type : Other, Cutting Machine

Capacity : High

Material : Aluminium, Other

Color : Blue

Product Type : Aluminium Profile Cutting Machine

Weight (kg) : Approx. 1500

CNC Plasma Cutting Machine

Type : Other, CNC Plasma Cutter

Capacity : Industrial Grade

Material : Other, Steel and Aluminum Structure

Color : Blue

Product Type : CNC Plasma Cutting Machine

Weight (kg) : Approx. 300kg

Bevel Cutting Laser

Type : Other, Fiber Laser Cutting Machine

Capacity : Industrialgrade, 24/7 operation

Material : Other, Carbon Steel, Stainless Steel, Aluminum, Alloy metals

Color : Other, Industrial Grey with Red highlights

Product Type : Laser Cutting Equipment

Weight (kg) : 3500 kg

messer gas regulator

Type : Other, Single Stage Regulator

Capacity : Adjusted According to Gas Type

Material : Other, Brass Body with Chrome Plating

Color : Other, Silver/Blue

Product Type : Gas Regulator

Weight (kg) : 1.2 kg (approx.)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS