Inkjet Marking

Price 1520000 INR/ Unit

Inkjet Marking Specification

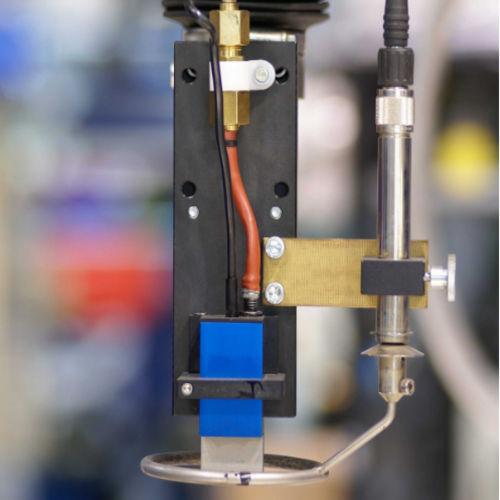

- Type

- Inkjet Marking Machine

- Material

- Mild Steel

- Capacity

- High Volume Printing

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital

- Cutting Function

- Marking Only

- Cooling System

- Air Cooling

- Drive Type

- Electrical

- Weight (kg)

- 35-40 kg

- Dimension (L*W*H)

- 420 x 320 x 310 mm

- Color

- Black and Silver

- Interfaces

- USB, Ethernet

- User Interface

- Intuitive Graphic Interface

- Operating Temperature

- 5C 45C

- Supported Languages

- Multi-language

- Mounting Type

- Tabletop / Inline

- Printing Speed

- Up to 130 meters/min

- Print Resolution

- Up to 256 x 256 dpi

- Display

- LCD Touch Screen

- Ink Type

- Continuous Inkjet (CIJ)

- Maintenance

- Low Maintenance with Easy Ink Replacement

- Power Consumption

- 50 W

- Applications

- Batch Coding, Date Printing, Serial Numbers

- Printing Distance

- 1-10 mm

- Supported Substrates

- Cartons, Plastics, Metals, Foils

- Print Height

- Up to 18 mm

About Inkjet Marking

Versatile Uses and Application Methods of Inkjet Marking

Inkjet Marking is widely used as an advanced solution for rapid, non-contact printing across manufacturing, packaging, and logistics industries. Common applications include barcoding, logo printing, product branding, and traceability marks. Easily integrated by tabletop or inline mounting, Inkjet Marking supports various substrates such as plastics, cartons, foils, and metal surfaces, ensuring flexible adaptation to diverse production environments. Its air-cooled, digital control system simplifies the application method, making operation and maintenance highly efficient for long-term industrial use.

FOB Port, Export Markets, and Packaging Details for Inkjet Marking

List price for Inkjet Marking machines is available upon Purchase Order submission, with streamlined delivery from major Indian FOB ports such as Mumbai and Chennai. Our products are securely packaged in robust export-grade wooden crates to ensure safe transit. We serve diverse main export markets, including Asia, Africa, and the Middle East. Customers can expect efficient order processing, custom packaging solutions, and prompt dispatch, facilitating a seamless international purchase and delivery experience every time.

FAQ's of Inkjet Marking:

Q: How do I operate the Inkjet Marking Machine for different substrates?

A: The Inkjet Marking Machine is equipped with an intuitive LCD touch screen and graphic user interface, allowing quick adjustments for carton, plastic, metal, or foil. Simply select the appropriate settings on the display for the substrate in use.Q: What are the main benefits of using a Continuous Inkjet (CIJ) system for marking?

A: The main benefits include high-speed, high-resolution marking with minimal downtime. The CIJ system offers dominant performance with low maintenance, easy ink replacement, and adaptability for various product types and production lines.Q: When should I replace the ink in the marking machine?

A: The system prompts ink replacement as needed. Due to its inestimable efficiency, maintenance intervals are minimal, ensuring consistent high-volume output without frequent interruptions.Q: Where can the Inkjet Marking Machine be mounted?

A: This model supports both tabletop and inline mounting, making it suitable for standalone setups or integration with automated production lines, based on your operational requirements.Q: What is the process for placing an order and receiving delivery?

A: Submit a purchase order to receive list price information. Upon order confirmation, secure export packaging is arranged, and delivery is initiated from primary Indian FOB ports, ensuring safe and prompt arrival to your location.Q: What additional applications can Inkjet Marking support aside from batch coding?

A: Beyond batch coding, the machine excels at date marking, serial numbering, barcoding, custom branding, and traceability applications across multiple industries, making it highly versatile for manufacturing and packaging operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Marking Category

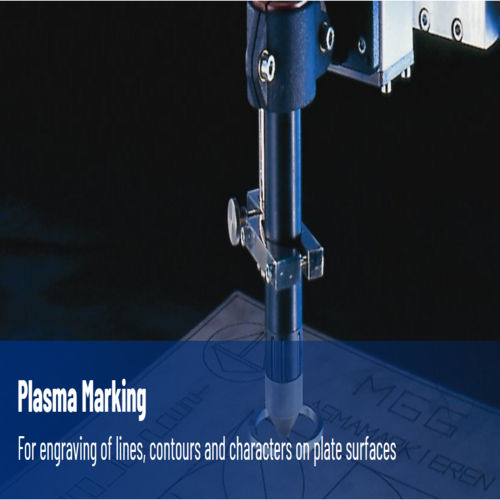

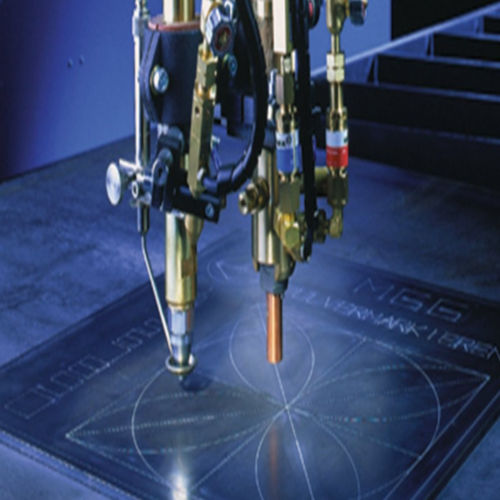

Plasma Marking

Price 185000 INR / Unit

Minimum Order Quantity : 01 Unit

Computerized : Yes

Weight (kg) : 450 kg

Automatic Grade : Automatic

Type : Plasma Marking Machine

Powder Marking

Price 190000 INR / Unit

Minimum Order Quantity : 01 Unit

Computerized : Yes

Weight (kg) : 650

Automatic Grade : Automatic

Type : Powder Marking Machine

Air Scribe Marking

Price 155000 INR / Unit

Minimum Order Quantity : 01 Unit

Computerized : No

Weight (kg) : Approx. 0.2 0.3 kg

Automatic Grade : SemiAutomatic

Type : Portable Air Scribe

Telesis Pinstamp

Price 152000 INR / Unit

Minimum Order Quantity : 01 Unit

Computerized : Yes

Weight (kg) : 24 kg

Automatic Grade : Automatic

Type : Dot Peen Marking Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS