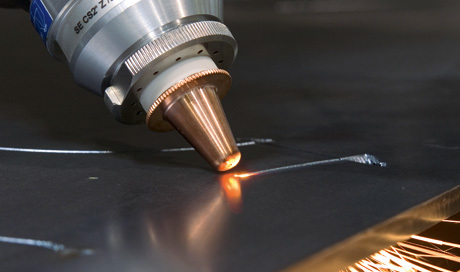

Bevel Cutting Laser

Bevel Cutting Laser Specification

- Drive Motor

- AC Servo Motor

- Product Type

- Laser Cutting Equipment

- General Use

- Industrial metal sheet and pipe cutting

- Material

- Carbon Steel, Stainless Steel, Aluminum, Alloy metals

- Type

- Fiber Laser Cutting Machine

- Capacity

- Industrial-grade, 24/7 operation

- Weight (kg)

- 3500 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- 030 m/min

- Cutting Thickness

- Up to 20 mm (material dependent)

- Cutting Function

- High-precision bevel cutting for metals

- Cooling System

- Water Cooling System

- Drive Type

- Servo Motor Drive

- Voltage

- 380V / 50Hz / 60Hz

- Dimension (L*W*H)

- 4600 mm x 2350 mm x 1800 mm

- Feature

- Multi-angle bevel cutting, high accuracy, stable performance

- Color

- Industrial Grey with Red highlights

- Motor

- High-performance servo motor

- Mechanical Precision

- 0.02 mm

- Software Detail

- Compatible with professional CAD/CAM software

- Cutting Method

- Laser (Fiber/CO2, dependent on configuration)

- Control System

- Advanced CNC (duplicated in list above, consolidated)

- Cutting Material

- Steel, Stainless Steel, Aluminum, Copper, Brass

- Cutting Area

- 1500 mm x 3000 mm

About Bevel Cutting Laser

Based in Coimbatore, Tamil Nadu, we are a leading service provider of Bevel Cutting Laser. This technique can cut materials having thickness for beveling up to 15 mm. Our cutting service includes various cutting techniques to offer best solutions. This cutting service is performed by laser cutting machine which has infinite rotation of the cutting head in its own axis. We are giving Bevel Cutting Laser service to our customers at affordable rates in a given time frame to them.

Features:

-

Completed within a stipulated time frame

-

Full after service support

-

Offers best cutting solutions

Other Details:

Types of bevel I, V, Y

Material thickness for beveling up to 15 mm

Material thickness for vertical cuts up to 25 mm

Max. Angle 45

Infinite rotation of the cutting head about its own axis

Interpolation of the bevel angel change on the fly from minimum to maximum torch inclination whilst cutting

Positive and negative bevel angles in one part are possible

Collision protection

Precision and Configurability for Industrial Demands

Engineered for versatility, this fiber laser cutter enables high-precision bevel cutting on an array of metals with configurable power settings (1000W6000W). Automated focusing, multi-angle capability, and advanced CNC controls ensure consistent, accurate results, even in demanding production cycles.

Tailored Workspace and Seamless Data Integration

Select between blade or exchange platform tables to optimize workflow. Import cutting files effortlessly through USB or Ethernet, with broad compatibility for professional CAD/CAM software, facilitating a streamlined transition from design to finished product.

Prioritizing Safety and Efficiency

Advanced safety mechanisms, including laser protection enclosures, emergency stop, and automatic smoke extraction, underscore a commitment to operator well-being and environmental safety. These measures make the machine suitable for high-capacity, uninterrupted operation.

FAQs of Bevel Cutting Laser:

Q: How does the auto-focusing laser head contribute to cutting precision?

A: The auto-focusing laser head adjusts focus in real-time based on material thickness and type, ensuring optimal beam alignment for consistent, high-quality bevel cuts. This automation minimizes errors and achieves tight tolerances, even during complex multi-angle operations.Q: What materials can be cut using this bevel cutting laser, and up to what thickness?

A: The machine proficiently cuts carbon steel, stainless steel, aluminum, copper, brass, and other alloy metals, with a cutting thickness of up to 20 mm depending on the material and chosen laser power.Q: When should I choose an exchange platform over a blade platform?

A: An exchange platform is ideal for continuous, high-volume production environments where quick material loading and unloading are critical to productivity, while a blade platform is suitable for lower-volume or simpler workflow needs.Q: Where can this laser cutting machine be installed, and what are the environmental operating requirements?

A: Install the machine in industrial settings with stable power supply (380V, 50/60Hz) and ample space (4600 x 2350 x 1800 mm). Maintain an ambient temperature between 540C and humidity below 80% (non-condensing) to ensure reliable operation.Q: What is the process for importing and executing cutting files?

A: Cutting files designed in professional CAD/CAM software can be imported directly using the machines USB or Ethernet interface. The CNC control system then manages execution, seamlessly translating digital designs into precise bevel cuts.Q: How does the machine ensure operator safety during cutting?

A: Safety features, including a protective laser enclosure, emergency stop, and automatic smoke extraction, safeguard operators from laser exposure, accidental contact, and fumes, establishing a secure working environment during all operations.Q: What are the key benefits of using this fiber laser cutting solution in manufacturing?

A: This system delivers high cutting precision, flexible multi-angle beveling, fast processing speeds, continuous operation capabilities, and integrated safety systems, making it a comprehensive solution for efficient and high-quality industrial metal fabrication.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Starlet Torch Kit System

Computerized : No

Cooling System : Other, Air cooled

General Use : Metal cutting, welding, brazing, heating

Color : Other, Torch: Brass, Hose: Red/Green

Mechanical Precision : Operator dependent

Dimension (L*W*H) : Torch Length: ~1520 cm; Hose Length: 25 meters

CNC Gas Cutting Machine

Computerized : Yes

Cooling System : Other, Advanced cooling

General Use : Industrial gas cutting applications

Color : Metallic, Other

Mechanical Precision : High mechanical precision

Dimension (L*W*H) : Varies with model configuration

Air Plasma Cutting Machine

Computerized : Yes

Cooling System : Air Cooled, Other

General Use : Industrial Metal Cutting

Color : Blue

Mechanical Precision : High

Dimension (L*W*H) : Compact

MS Sheet Cutting Machine

Computerized : Yes

Cooling System : Water Cooling, Other

General Use : Industrial MS Sheet Processing

Color : Blue

Mechanical Precision : High

Dimension (L*W*H) : Standard Dimensions

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS