Bevel Head Skew Rotator Infinity

Bevel Head Skew Rotator Infinity Specification

- Drive Motor

- Integrated servo drive

- Product Type

- Cutting Machine Accessory

- General Use

- For profile, bevel, and angled cutting applications

- Material

- High-grade steel and alloy components

- Type

- Bevel Head Skew Rotator

- Capacity

- Heavy duty, suitable for industrial applications

- Weight (kg)

- Approx. 25-30 kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- Variable, up to 10,000 mm/min depending on setup

- Cutting Thickness

- Up to 200 mm (Depends on cutting torch and material)

- Cutting Function

- Bevel head, skew rotator for precise angled cutting

- Cooling System

- Integrated water cooling system

- Drive Type

- Servo motor drive

- Voltage

- 220-415 V, 3 phase

- Dimension (L*W*H)

- 340 x 220 x 350 mm

- Feature

- Infinite rotator head for multi-axis movement

- Color

- Silver/Grey

- Motor

- Precision servo motor

- Mechanical Precision

- 0.01 mm

- Software Detail

- Advanced CNC controller included

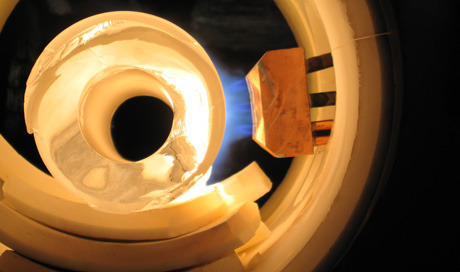

- Cutting Method

- Thermal/Oxy-fuel/Plasma (rotator attachment)

- Control System

- CNC-based digital control

- Cutting Material

- Carbon steel, stainless steel, alloy steel

- Cutting Area

- Customizable as per requirement

- Plasma Power Source Compatibility

- Compatible with Hypertherm, Kjellberg, and other leading brands

- Gas Supply

- Oxygen, air, or mixed gas

- Bevel Types

- K, V, X, Y, and custom bevels

- Axis Count

- 5-axis control

- Noise Level

- <80 dB

- User Interface

- Touchscreen HMI

- Safety Features

- Overload protection, Emergency stop, Enclosed cable routing

- Installation Support

- On-site installation and training available

- Cut Edge Quality

- Smooth, minimal dross

- Repeat Positioning Accuracy

- ±0.05 mm

- Torch Rotation Angle

- ±45 degrees

- Input Power Frequency

- 50/60 Hz

- Operating Temperature

- 0°C to 45°C

Bevel Head Skew Rotator Infinity Trade Information

- Main Domestic Market

- All India

About Bevel Head Skew Rotator Infinity

We are a leading service provider for the Bevel Cutting Plasma.With the assistance of our professionals, we are engaged in offering service of Bevel Head Skew Rotator Infinity. Our cutting service is highly reliable & tool use for executing service has quick torch focal point adjustment & unlimited c axis rotation. This cutting service is executed as per industry norms by our professionals who have vast knowledge.

Features:

Torch focal point adjustment

Cost effective

Automatic torch height control

Other Details:

AC drives for high performance.

Programmable arc current, arc voltage, and bevel angle

Infinite C-axis rotation at a rate of 75 RPM, reduces cut cycle and programming time

Quick torch focal point adjustment for easy consumable changeover

Lateral and vertical torch decoupler collision detection to prevent torch damage in event of a collision

Automatic torch height control by analog arc voltage with an accuracy of +/- .006 inches

(+/- 0,15 mm) so part accuracy is maintained during bevel cutting

Resultant piece part bevel angles of +45 degrees through -45 degrees

The most successful plasma bevel cutting head ever

Compound Skew Axis System for high flexibility and productivity

No cumbersome arc segments to risk collision or inhibit the cut

Unlimited C Axis rotation

Precision Everything: Multi-Axis Cutting Excellence

Engineered with a 5-axis control system and infinite rotator head, the Bevel Head Skew Rotator Infinity delivers unmatched flexibility in creating complex bevels such as K, V, X, Y, and custom profiles. Achieve superior mechanical precision (0.01 mm) and repeat positioning accuracy (0.05 mm), meeting the most stringent industrial demands for quality and reliability.

Intuitive Control & Seamless Operation

Experience streamlined operations with the advanced CNC controller and touchscreen HMI. Operators benefit from user-friendly interfaces and programmable automation, significantly reducing setup times. The adjustable cutting speed (up to 10,000 mm/min) and servo-driven mechanisms enhance productivity without compromising on cut edge quality.

Robust Build, Trusted Support

Fabricated from high-grade steel and alloy components, the system is designed for long-term heavy-duty industrial applications. On-site installation and training support ensure your team is equipped for optimal use from day one, and comprehensive safety featureslike overload protection, emergency stops, and enclosed cablessafeguard operations.

FAQs of Bevel Head Skew Rotator Infinity:

Q: How does the Bevel Head Skew Rotator Infinity achieve precise angled cuts?

A: The Bevel Head Skew Rotator Infinity utilizes a 5-axis servo-driven mechanism with a precision infinite rotator head, enabling 45-degree torch rotation. This design allows for highly accurate angled and bevel cuts, with repeat positioning accuracy of 0.05 mm on various metals.Q: What types of bevels can be created with this machine?

A: This system is capable of producing K, V, X, Y, and custom bevels. Its versatile 5-axis control and customizable cutting area accommodate complex profiles and multi-angle requirements tailored to individual project needs.Q: When is installation and training support provided?

A: On-site installation and comprehensive training are available upon delivery to customers in India, ensuring proper setup and familiarization before operational handover, so your team can quickly achieve full production capability.Q: Where can the Bevel Head Skew Rotator Infinity be installed?

A: As a heavy-duty, industrial-grade solution, it is suitable for fabrication shops, manufacturing plants, and metalworking facilities. The customizable cutting area and compatibility with major plasma power sources make it adaptable to both new and existing production environments.Q: What is the process for changing bevel types during operation?

A: Switching between bevel types is performed through the touchscreen HMI. Simply select the desired bevel profile from the CNC controllers programming menu and the servo motors will automatically adjust the torch angle and positioning, minimizing downtime.Q: How does the cutting system ensure safety during use?

A: Safety is integral, featuring overload protection, an emergency stop system, and enclosed cable routing. These measures reduce risk to operators and equipment, helping maintain a secure work environment.Q: What benefits does the integrated water cooling system provide?

A: The built-in water cooling system maintains optimal working temperatures during prolonged, heavy-duty cutting, preventing overheating of the cut head and servo motors to ensure consistent high-quality results and longevity of components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

CNC Plasma Cutting Machine

General Use : Metal Fabrication

Cutting Thickness : Up to specified thickness

Cooling System : Other, Integrated

Computerized : Yes

Cutting Speed : HighSpeed

Product Type : CNC Plasma Cutting Machine

OmniBevel Software

General Use : Bevel cutting, plate processing, metal fabrication

Cutting Thickness : Depends on machine/machine settings

Cooling System : Other, Machine dependent

Computerized : Yes

Cutting Speed : Dependent on connected CNC machine

Product Type : CAD/CAM Software

Straight Oxy Fuel Cutting

General Use : Metal fabrication and industrial cutting

Cutting Thickness : Varies based on material

Cooling System : Other, Not Provided

Computerized : Yes

Cutting Speed : Not Provided

Product Type : Straight Oxy Fuel Cutting

Griflam Heating

General Use : Industrial heating and cutting

Cutting Thickness : Up to 80 mm (based on application)

Cooling System : Other, Air/Water cooled

Computerized : No

Cutting Speed : Depends on material & application

Product Type : Industrial Heating Equipment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS