OmniBevel Software

OmniBevel Software Specification

- Drive Motor

- Machine-specific

- Product Type

- CAD/CAM Software

- General Use

- Bevel cutting, plate processing, metal fabrication

- Material

- Supports steel, aluminum, stainless steel and more

- Type

- Bevel Cutting Software

- Capacity

- Advanced nesting and bevel calculations

- Weight (kg)

- Not applicable (software-only product)

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- Dependent on connected CNC machine

- Cutting Thickness

- Depends on machine/machine settings

- Cutting Function

- Automatic and manual bevel cutting, 3D cutting paths

- Cooling System

- Machine dependent

- Drive Type

- Compatible with multiple CNC drive systems

- Voltage

- Software integration for machines with various voltage support

- Dimension (L*W*H)

- Digital Product

- Feature

- User-friendly interface, advanced nesting algorithms, support for complex contours

- Color

- Software GUI - Multicolor

- Motor

- Machine-dependent

- Mechanical Precision

- Enhanced via software algorithms

- Software Detail

- OmniBevel CAD/CAM Software for precise cutting, design and nesting

- Cutting Method

- Automatic and manual beveling

- Control System

- Compatible with major CNC brands

- Cutting Area

- Depends on machine integration

- Cutting Material

- Steel, aluminum, stainless steel, others

About OmniBevel Software

We are a Leading Service Provider for the Cutting Software.We are Leading Service Provider of OmniBevel Software.

OmniBevel 2013 is the professional software product for bevel cutting. It represents straight cuts, cylindrical holes, exact bevel angles and parts with absolute dimensional accuracy. The application is also characterized by enormous flexibility. Almost all possible technology parameters and operation details can be adjusted.

The intelligent defaults based on the technology database often render any manual intervention redundant. This ensures efficient operations whilst meeting the highest quality standards.

OPTIMUM HARMONIZATION AND PRECISE INSTRUCTIONS

To achieve quality bevel cuts the NC code generated must be matched exactly to the capabilities and performance of the machine used. Lateral and angular offsets must be allowed for on all cuts. Lead-ins and lead-outs as well as joining macros between individual contour areas must be placed in such a way that no damage to the contours occurs. Bevel cuts make the highest demands on the programming of the cutting plan.

MAKES THE MOST OF YOUR MACHINE

OmniBevel 2013 is a postprocessor module with graphical user interface. It inserts bevel information and technological requirements into NC plans in such a manner that the machine used gives optimum cutting results in automatic operation. With OmniBevel 2013 you are using the tool which will guarantee you the best quality when bevel cutting. OmniBevel 2013 brings out everything possible from your machine with a bevel unit.

Key Features:

Full control of your Oxyfuel, Plasma or Laser cutting is dramatically simplified

Bevels are accurate " guaranteed

Shorten production time

Increase quality and productivity for bevel cutting

Determines the amount of automation that fits your situation

Analyses the contours and provides suitable, customizable technologies for optimal cutting

Implements the optimal parameters to insure the highest quality cutting

Customer optimizable databases are supplied for many types of cutting processes

Process of bevel cutting down broken down into optimal routines perfectly matched to your real-life situations

Advanced Bevel Cutting Automation

OmniBevel merges robust CAD/CAM design with advanced automation for both manual and automatic beveling processes. Its software algorithms enhance precision and reduce human error, ensuring intricate contour cuts and efficient nesting. Macros and scripting support further personalize automation, optimizing productivity and adaptability for diverse fabrication needs.

Compatibility and Integration

This software is compatible with standard PCs and supports Windows natively, with virtualization options for other operating systems. OmniBevel integrates smoothly with popular plasma, oxy-fuel, and laser cutting machinery, accommodating a wide array of CNC systems and material types. The flexible design allows straightforward connectivity in varied workshop environments.

Comprehensive User Support and Customization

User onboarding is facilitated through included training, while a customizable tool database and comprehensive scripting allow adaptation for multiple machines. With free updates for the first year and extensive language options, users receive ongoing support and the flexibility to match their operational requirements, ensuring peak performance throughout their use.

FAQs of OmniBevel Software:

Q: How does OmniBevel support different operating systems?

A: OmniBevel is optimized for Windows environments but can also run on other systems using virtualization solutions. This allows users on platforms like macOS or Linux to install and operate the software efficiently, ensuring maximum compatibility.Q: What file formats can OmniBevel import and export?

A: OmniBevel supports a variety of industry-standard formats, including DXF, DWG, and ESSI for import and export. This flexibility helps users integrate designs from other CAD platforms and easily share projects across systems.Q: When are software updates provided, and what do they include?

A: Upon purchase, users receive one year of free software updates. These updates typically feature improvements in functionality, performance tweaks, and occasional interface enhancements to ensure your software stays current and reliable.Q: Where can OmniBevel be used and what hardware is required?

A: OmniBevel can be used in any facility equipped with a standard PCrequiring at least 4GB RAM and 500MB storage. Its diverse connectivity with major CNC brands enables seamless integration into most plasma, oxy-fuel, and laser cutting settings.Q: What is the process for integrating OmniBevel with existing CNC machines?

A: Integration is straightforward due to OmniBevels support for multiple drive systems and control interfaces. Users can connect the software to compatible machines, import designs, configure cutting paths, and use the customizable tool database to match machine specifications.Q: How does OmniBevel benefit metal fabrication workflows?

A: OmniBevel enhances precision cutting through advanced nesting algorithms and 3D path visualization, optimizing material usage and reducing waste. The user-friendly interface and robust automation help accelerate project timelines and improve output consistency.Q: What user support and training options are available with OmniBevel?

A: Every OmniBevel purchase includes comprehensive user training and multi-language interface support. Additionally, users are backed by technical support and guidance to ensure smooth onboarding and maximum benefit from the softwares features.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

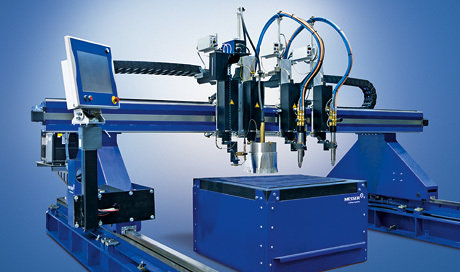

CNC Flame Cutting Machine

General Use : Metal fabrication industrial cutting applications

Product Type : CNC Flame Cutting Machine

Computerized : Yes

Feature : Other, High precision reliable cutting automated operation

Mechanical Precision : High precision

Dimension (L*W*H) : Custom dimensions depending on model

Metal Laser Cutting

General Use : Metal Sheet and Plate Cutting

Product Type : Metal Laser Cutter

Computerized : Yes

Feature : Other, Rustproof, Durable Frame, High Speed, Precise Finish

Mechanical Precision : 0.01 mm

Dimension (L*W*H) : 4800 mm x 2300 mm x 1700 mm

Fiber Blade - Compact Laser Cutting Machine

General Use : Industrial Laser Cutting

Product Type : Fiber Laser Cutting Machine

Computerized : Yes

Feature : High precision fully automated fast cutting, Other

Mechanical Precision : Very High

Dimension (L*W*H) : Large industrialsized

Star Torch Kit System

General Use : Metal Cutting

Product Type : Star Torch Cutting Kit

Computerized : No

Feature : Other, Portable, High Precision, Easy to Operate

Mechanical Precision : High

Dimension (L*W*H) : Standard Kit Dimensions

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS