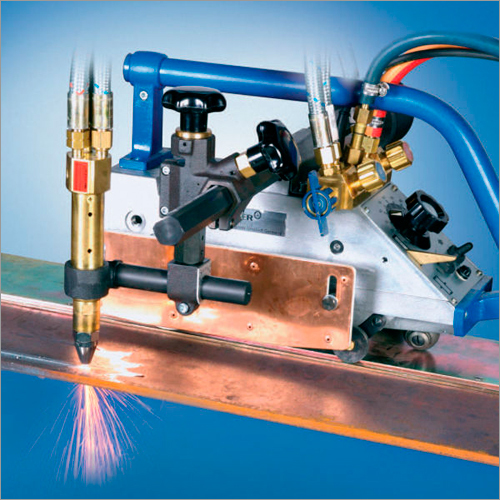

Straight Cutting Oxy Fuel

Straight Cutting Oxy Fuel Specification

- Product Type

- Straight Cutting Oxy Fuel

- General Use

- Metal Plate Cutting

- Material

- Mild Steel, Stainless Steel

- Type

- Oxy Fuel Cutting Machine

- Capacity

- Heavy Duty Operation

- Weight (kg)

- Approx. 10 - 12 kg

- Computerized

- No

- Automatic

- No

- Cutting Speed

- 50 - 750 mm/min

- Cutting Thickness

- Up to 300 mm (depends on nozzle and plate)

- Cutting Function

- Straight Line Cutting

- Cooling System

- Air Cooled

- Drive Type

- Manual / Mechanical

- Voltage

- Not Required (Manual Operation)

- Dimension (L*W*H)

- 430 mm x 230 mm x 270 mm

- Feature

- Portable, Easy operation, Rugged Construction

- Color

- Silver / Metallic

- Mechanical Precision

- High accuracy assisted by guide rail

- Cutting Method

- Oxy-Fuel Flame

- Control System

- Manual

- Cutting Material

- Mild Steel, Stainless Steel

- Cutting Area

- Customized as per requirement

- Accessory Options

- Guide rail, hose, pressure regulator (optional)

- Operation Mode

- Handheld or guided rail

- Bevel Cutting Capability

- Optional, with attachments

- Number of Nozzles

- Single nozzle

- Surface Finish

- Clean, uniform cut edge

- Torch Type

- Straight line cutting torch

- Usage Environment

- Workshops, construction sites, fabrication units

- Ignition

- Manual

- Gas Compatibility

- Oxygen and fuel gases such as Acetylene, LPG

Straight Cutting Oxy Fuel Trade Information

- Main Domestic Market

- All India

About Straight Cutting Oxy Fuel

We are a Leading Service Provider for the Straight Cutting Oxyfuel.We have been successfully satisfying the diverse needs of our esteemed clients by providing Straight Cutting Oxyfuel. Our offered cutting service has totally integrated height sensing with no external parts. Our cutting service is well known in the market due to its cost effectiveness & it does need for tools to change nozzles. Customers can avail this cutting service from us as per their need at their budgetary constraints.

Features:

Reliable operation

Does not require tools to change nozzle

Timely executing

Other Details:

Only the cutting nozzles are changed when going from one material size to another

Throttle valves controlling the flow of gas and oxygen can be replaced individually

Oxygen consumption is lower, which reduces the cost of utilities

This is achieved without any loss of cut quality or cutting speed

The arrangement of the nozzle holes and preheat slots make cleaning easy with MG nozzle cleaners

Each nozzle is individually tested for assured quality

No need for tools to change nozzles. This reduces the cost of stocking many nozzle sizes

Risk of misaligning the torch when changing nozzles is thus eliminated

Drastically reduces set-up times

Can be used with the OL-200 oxyfuel lifters

MS 932 System:

MS 932 Torch including throttle valves and check valves

Nozzles for all fuel gases

Supply hoses- NFPA rated

Regulation equipment

Torch holder- mounts to all cutting machine

Additional Information:

Precision Straight-Line Cutting

Engineered for accurate straight-line cuts, this oxy fuel torch is suitable for both hand-held or guided rail operations. Its single-nozzle design produces uniform and clean cut edges every time, meeting the needs of demanding fabrication and construction projects.

Versatile Fuel Gas Compatibility

Compatible with oxygen and various fuel gases, including acetylene and LPG, the machine adapts to available resources and user preference. This versatility means it fits seamlessly into diverse industrial environments throughout India and beyond.

Heavy Duty and Portable

Although it weighs approximately 10-12 kg, this oxy fuel cutter is regarded for its portability and sturdy build. Its rugged construction and air-cooled system allow for continuous, heavy-duty operation on a range of cutting applications, whether in the workshop or out on-site.

FAQs of Straight Cutting Oxy Fuel:

Q: How does the straight cutting oxy fuel machine operate?

A: The machine operates manually or with mechanical assistance, using a combination of oxygen and a chosen fuel gas (such as acetylene or LPG) to create a precise flame. The operator can guide the torch by hand or use it with an optional guide rail for enhanced accuracy.Q: What materials and thicknesses can this machine cut?

A: It is ideal for cutting mild steel and stainless steel, handling thicknesses up to 300 mm depending on the nozzle size and plate. This makes it suitable for heavy-duty applications in fabrication and construction.Q: Where is this equipment typically used?

A: This oxy fuel cutting machine is commonly deployed in workshops, construction sites, and fabrication units where reliable straight-line cutting of metal plates is required. Its portability supports both in-house and field operations.Q: What is the recommended process for achieving a clean cut edge?

A: To achieve a clean, uniform cut, select the correct nozzle size and adjust the gas pressures according to the thickness and type of metal. Using the guide rail accessory can further enhance the straightness and quality of the cut edge.Q: When is bevel cutting possible with this equipment?

A: Bevel cutting is possible when optional attachments are fitted to the torch. These accessories allow for angled cuts, adding to the machines versatility for different fabrication tasks.Q: What benefits does manual operation provide?

A: Manual operation offers straightforward setup, portability, and ease of use, with no dependency on electrical power. This is advantageous in remote locations or where electrical access is limited.Q: What accessories are available to improve cutting performance?

A: Optional accessories include a guide rail for enhanced precision, hoses for secure gas delivery, and pressure regulators for optimal flame control. These upgrades help tailor the machine to specific cutting requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Secaator CNC Profile Cutting Machines

Type : Other, CNC Cutting Machine

Automatic : Yes

Cutting Material : Metals

Computerized : Yes

General Use : Metal profile cutting

Color : Blue

CNC Cutting Machines

Type : Plasma Cutting Machine, Other

Automatic : Yes

Cutting Material : Steel Aluminum etc.

Computerized : Yes

General Use : Industrial Cutting

Color : Blue

Air Plasma Cutting Machine

Type : CNC Cutting Machine, Other

Automatic : Yes

Cutting Material : Metal

Computerized : Yes

General Use : Industrial Metal Cutting

Color : Blue

Messer flow meter regulator

Type : Other, Single stage with flow meter

Automatic : No

Cutting Material : nan

Computerized : No

General Use : Gas flow regulation for industrial welding/cutting

Color : Other, Silver and transparent

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS