Hand Cutting Nozzles

Hand Cutting Nozzles Specification

- Drive Motor

- Manual/Hand Operated

- Product Type

- Oxy-Fuel Cutting Nozzle

- General Use

- For Cutting Steel & Metals with Oxy-Fuel/Gas Apparatus

- Material

- Brass/Copper Alloy

- Type

- Hand Cutting Nozzle

- Capacity

- Suitable for Light to Heavy-Duty Cutting

- Weight (kg)

- Approx. 0.1 to 0.2 kg per Nozzle

- Computerized

- No

- Automatic

- No

- Cutting Speed

- Depends on Thickness and Gas Pressure

- Cutting Thickness

- 1 mm to 300 mm (Varies by Nozzle Size)

- Cutting Function

- Hand Cutting for Oxy-Fuel/Gas Applications

- Cooling System

- Air-Cooled

- Drive Type

- Manual

- Dimension (L*W*H)

- Standard Nozzle Size (varies by model)

- Feature

- Robust Construction, Precision Jet, Long Life

- Color

- Golden/Brass

- Mechanical Precision

- High Precision Flame Jet

- Cutting Method

- Oxy-Fuel/Gas Flame Cutting

- Control System

- Manual Control

- Cutting Material

- Mild Steel, Carbon Steel, Low Alloy Steel

- Packaging

- Box/Individual Polybag

- Compatible Gases

- Acetylene, Propane, LPG, Natural Gas

- Nozzle Bore Size

- Vary by Cutting Thickness (e.g. 1/32 to 1/8)

- Pressure Settings

- Depends on Gas Type and Thickness

- Manufacturing Standard

- IS, BS, or as per Customer Requirement

- Surface Finish

- Machined and Polished

- Nozzle Series

- ANM, PNM, A-Type, etc.

- Operating Temperature

- Ambient to High (depending on gas flame)

- Usage Environment

- Workshops, Fabrication, Construction

- Thread Type

- Standard International/Indian Threads

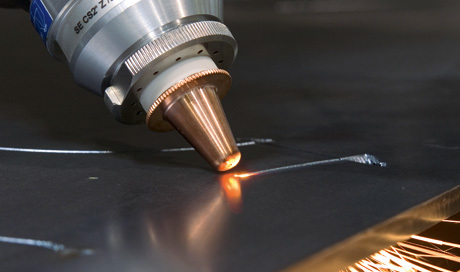

About Hand Cutting Nozzles

We have been serving our respected clients for the past 10 years by manufacturing and supplying a wide range of Hand Cutting Nozzles. These are designed with utmost precision and fabricated using quality grade components at our well-equipped facility. These nozzles are widely used in combination torch systems and hand cutting torches. They are highly appreciated by our clients for their strong construction, high durability, and efficient functionality. Offered Hand Cutting Nozzles are well tested before launching in the market so as to remove any flawed product.

Features:

-

High dimensional accuracy

-

Prolonged service life

-

Needs little or no maintenance

Implementation:

For combination torch systems

For hand cutting torches

Cutting range to 19 5/8 inch (500 mm)

Advantages:

High cutting quality and optimum cutting output because of careful material selection

High operating reliability through ideal matching of torches and nozzles

Long lifetimes thanks to surface protection

Guaranteed quality assurance through individual testing

Scope of supply:

Ring/Slot cutting nozzles

Block cutting nozzles

Gas mixing cutting nozzles

Accessories

Precision Engineering for Professional Results

Our hand cutting nozzles are crafted from high-quality brass and copper alloys, delivering superior durability and heat resistance. The machined and polished surface finish ensures a consistent, high-precision flame jet, crucial for clean, accurate metal cuts. Every nozzle is subjected to strict quality checks and manufactured in accordance with IS, BS, or customized standards.

Versatile Applications and Gas Compatibility

These nozzles accommodate a wide range of gases like acetylene, propane, LPG, and natural gas. Whether youre working on light-duty fabrication or heavy-duty construction, different nozzle series and bore sizes are available to meet specific cutting thickness requirements. Their robust construction makes them dependable for diverse industrial environments.

Easy Handling and User Convenience

Operating entirely manually with no computerized components, the nozzles are easy to install and maintain. Air-cooling ensures prolonged operational life, while their ergonomic designs support comfortable hand usage. Each nozzle is individually packed, offering protection and ease of inventory management for distributors and manufacturers.

FAQs of Hand Cutting Nozzles:

Q: How do I select the appropriate hand cutting nozzle for different gas types and metal thicknesses?

A: Select a nozzle based on the gas youre usingoptions include acetylene, propane, LPG, or natural gasand the thickness of the metal to be cut. Reference the nozzles bore size (ranging from 1/32 to 1/8) and series (such as ANM or PNM), as each is designed for specific gases and cutting thicknesses between 1 mm and 300 mm.Q: What process is followed when using hand cutting nozzles for oxy-fuel/gas cutting?

A: The process involves fitting the appropriate nozzle to the cutting torch, setting gas pressures according to the metal thickness and gas type, and igniting the flame using a manual control system. The nozzles precision jet ensures an accurate and controlled cut along the desired line, delivering clean results on steel and other metals.Q: When and where are these hand cutting nozzles typically used?

A: Hand cutting nozzles are widely used in settings like metal workshops, fabrication plants, and construction sites where versatile and manual oxy-fuel/gas cutting is required. They perform reliably in both ambient and elevated temperature environments, depending on the gas used and the intensity of the cut.Q: What are the benefits of using machined and polished brass/copper nozzles?

A: Nozzles made from machined and polished brass/copper alloys offer increased durability, corrosion resistance, and heat dissipation. The precision manufacturing results in a consistent flame jet, prolonging nozzle life and enhancing the quality of every cut.Q: How should nozzles be maintained and stored for optimum longevity?

A: After use, clean the nozzle to avoid blockages and store it in the provided individual polybag or box. Routine maintenance prevents surface buildup and ensures continued high-performance operation, helping the nozzle last longer and perform better in demanding conditions.Q: What packaging options are available for hand cutting nozzles?

A: Nozzles are available in individual polybags or boxed packaging, ensuring protection during transit and easy inventory management. Suppliers offer tailored packaging to meet distribution and storage needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

ProBlade Cutting Machine

Computerized : Yes

Feature : Other, Highspeed operation, Dust extraction port, Userfriendly touchscreen interface

Automatic : Yes

Material : Other, Mild steel, Stainless steel, Acrylic, Plastic, Wood

Dimension (L*W*H) : 1100 x 750 x 1000 mm

Type : Automatic Cutting Machine

CNC Gas Cutting Machine

Computerized : Yes

Feature : Precision cutting; CNC control; robust construction, Other

Automatic : Yes

Material : Other, Stainless steel components

Dimension (L*W*H) : Varies with model configuration

Type : Gas Cutting Machine

Easy to Operate Oxy Fuel Bevel Cutting Units

Computerized : No

Feature : Easy to operate, Other

Automatic : No

Material : Other, Metal components

Dimension (L*W*H) : Compact design

Type : Manual, Other

Electrode Holder

Computerized : No

Feature : Other, Heat Resistant, Ergonomic Design, Heavy Duty, Insulated Handle

Automatic : No

Material : Other, Brass, Copper, Steel, High Quality Plastic

Dimension (L*W*H) : 21cm x 7cm x 3cm

Type : Other, Electrode Holder

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS