OmniSigma Software

OmniSigma Software Specification

- Drive Motor

- Machine Dependent

- Product Type

- Cutting Programming Software

- General Use

- CNC Plasma, Flame, Laser, Waterjet Machine Programming

- Material

- Compatible with Steel, Stainless Steel, Aluminium

- Type

- Industrial Software Tool

- Capacity

- Multiple Machine Support

- Weight (kg)

- Digital Product

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- Machine Dependent; Supports High-Speed Programming

- Cutting Thickness

- Depends on machine configuration

- Cutting Function

- Automated Nesting, Path Optimization

- Drive Type

- Servo Motor Drive

- Voltage

- 220V/380V

- Dimension (L*W*H)

- Digital Product

- Feature

- High Accuracy, User-friendly Interface, Real-time Simulation

- Color

- Digital Product

- Motor

- Machine Dependent

- Mechanical Precision

- Programming precision up to 0.01 mm

- Software Detail

- OmniSigma Nesting/Programming Software

- Cutting Method

- Nesting, Tool Path Generation

- Control System

- CNC Compatible, Customizable Post-Processor

- Cutting Area

- 1800 x 3000 mm

- Cutting Material

- Steel, Stainless Steel, Aluminium Sheets

About OmniSigma Software

We are a Leading Service Provider for the Cutting Software.We are Leading Service Provider of OmniSigma Software.

OmniSigma 2013 is the most comprehensive tool offering the ultimate in advanced nesting and advanced motion-optimized NC programming to minimize scrap and increase machine productivity. It sets new standards for cost-optimized process technologies, multi-vendor environments plus extensive interfaces for integration with ERP/MRP. For common-line cutting, bridge cutting and chain cutting.

OmniSigma 2013 gives you the ability to track jobs and remnants to help streamline production. OmniSigma 2013 is ideal for all profile cutting machines, including laser, plasma, oxyfuel, waterjet, router and combination machines.

SAFE YOUR RESOURCES AND SIMPLIFY YOUR WORK

OmniSigma 2013 is the high-end solution in the successful product range of MesserSoft and one of the most powerful cutting solutions worldwide. OmniSigma 2013 is powered by SigmaNEST from SigmaTEK. With its ultimate functionalities it saves engineering time through simplified programming and more efficient machine output. You reduce or eliminate scrap dramatically, handle more orders in less time and extend life of your machine consumables.

Your machine throughput is faster, your work flow improves. Beside a better control of inventory you simplify work order tracking from beginning to end. Streamlining of planning with accurate time and cost estimates before cutting makes you become a business partner, your customers like to work with.

BEST IN CLASS FUNCTIONALITIES

You just need one software to program all major profile cutting and punching machines. You gain maximum flexibility in file conversion and importation. Challenging nesting and cutting tasks are done automatically by OmniSigma 2013. For future use you save custom shapes into the standard part library. Nesting provides maximum yield per sheet. Higher levels of continuous cutting with minimal pierces are easy to reach. For maximum consumption of remnants OmniSigma 2013 effectively manages your raw material inventory. Through the OmniSigma 2013s open architecture your systems are completely customizable. Moreover it provides users with the maximum amount of flexibility in post processor configurations.

Key Features:

Automatic part pattern recognition

Part-in-part nesting

Accurate cost and time estimators

Adaptive nesting for multi-head machines

Drag, drop and bump features

Automatic and manual true shape nesting

Automatic NC toolpath generation and optimization

Extensive, fully customizable standard shapes library

Techno, Trueshape and PowerPack Editions

Efficient CNC Programming for Industrial Applications

OmniSigma Software is designed to optimize CNC cutting processes across multiple machine types, including plasma, flame, laser, and waterjet. By utilizing powerful nesting algorithms and real-time simulation, it maximizes material utilization and accuracy. The software accommodates single or multi-user licensing and supports upgrades through official releases, ensuring you always benefit from the latest advancements. With multi-material compatibility and customizable post-processors, OmniSigma seamlessly integrates into diverse industrial environments.

Flexible Installation and User Support

Installation is available both online and offline, adapting to various factory or office settings. A minimum of 2GB RAM, 2GHz processor, and 250MB storage are required. New users receive detailed training and ongoing support via remote access and email, empowering teams to unlock the full potential of their CNC equipment from the start.

FAQs of OmniSigma Software:

Q: How do I install OmniSigma Software on my CNC workstation?

A: OmniSigma Software can be installed either online or offline on any workstation running Windows 7, 8, 10, or 11. Ensure your system meets the minimum requirements2GB RAM, 2GHz processor, and 250MB of free disk space. Follow the installation guide provided upon purchase for a seamless setup.Q: What file formats are supported for import and export?

A: OmniSigma supports importing DXF, DWG, ESSI, and G-code files, and can export in G-code, ESSI, and other CNC-specific formats. This versatility allows seamless integration with a broad range of CAD software and CNC machines.Q: Where can I get technical support if I encounter an issue?

A: Technical support is readily available via remote assistance and email. Whether youre a distributor, manufacturer, service provider, or end-user in India, our support team is committed to resolving your queries efficiently.Q: What are the main benefits of using OmniSigma Software?

A: OmniSigma enhances operational efficiency through automated nesting, path optimization, real-time simulation, and high programming accuracy up to 0.01 mm. It supports a wide range of materials and CNC machines, and its intuitive interface ensures rapid learning and productivity.Q: How does the user training process work?

A: Comprehensive training is included with every initial purchase. This ensures new users can effectively operate the software from day one, learning best practices and advanced techniques tailored to their specific CNC setup.Q: When should I upgrade my OmniSigma Software?

A: Upgrades are recommended whenever new official releases become available. These updates provide feature enhancements, improved compatibility, and security updates, ensuring your software remains up-to-date with industry standards.Q: What types of machines and materials is OmniSigma compatible with?

A: OmniSigma supports programming for CNC plasma, flame, laser, and waterjet machines. Its compatible with steel, stainless steel, and aluminium sheets, and can accommodate various machine-driven cutting methods and configurations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Automatic Cutting Machine

Product Type : Automatic Cutting Machine

Automatic : Yes

Feature : Other, Automatic operation high precision CNCbased

Material : Highgrade steel for machine components, Other

General Use : Industrial cutting

Color : Blue

Bevel Oxy Fuel Cutting

Product Type : Cutting Machine

Automatic : Yes

Feature : Other, Precision bevel cutting

Material : Steel

General Use : Industrial cutting

Color : Black

Steel Mill Equipment

Product Type : Industrial Metal Cutting Machine

Automatic : Other, Fully Automatic Operation

Feature : Other, Heavy Duty, High Precision, Robust Construction

Material : Other, Steel, Mild Steel, Stainless Steel Components

General Use : Steel Plant, Rolling Mill, Industrial Metal Processing

Color : Other, Industrial Blue & Grey

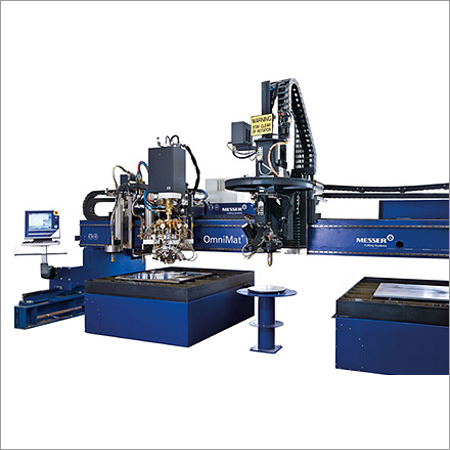

Omnimat CNC Thermal Cutting Machine

Product Type : Thermal Cutting Machine

Automatic : Yes

Feature : Other, High Precision and Flexibility

Material : Other, Durable Steel

General Use : Industrial

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS