Griflam Heating

Griflam Heating Specification

- Drive Motor

- Electric

- Product Type

- Industrial Heating Equipment

- General Use

- Industrial heating and cutting

- Material

- Steel / Iron (As required)

- Type

- Griflam Heating System

- Capacity

- Industrial/Heavy Duty

- Weight (kg)

- Varies as per size

- Computerized

- No

- Automatic

- Optional

- Cutting Speed

- Depends on material & application

- Cutting Thickness

- Up to 80 mm (based on application)

- Cutting Function

- Precision cutting and heating

- Cooling System

- Air/Water cooled

- Drive Type

- Electric

- Voltage

- 220-440 V

- Dimension (L*W*H)

- As per model

- Feature

- High temperature, Uniform heating

- Color

- Standard (Customizable)

- Motor

- Heavy duty electric motor

- Mechanical Precision

- High precision control

- Cutting Method

- Thermal heating and cutting

- Control System

- Manual and optional automatic

- Cutting Material

- Steel, Iron, Alloys

- Cutting Area

- Customized as per requirement

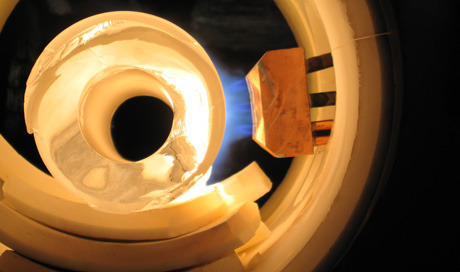

About Griflam Heating

Offering you a complete choice of products which include griflam heating.We are Leading Manufacturer & Exporter of Griflam Heating.

Implementation:

Multifunctional heating equipment for professional applications

For pre and post heating when welding and cutting, stress relieving, normalizing and flame hardening, and heat conversion of metals, glass and quartz glass, fusing of powder coatings, preheating of steel ingots, flame straightening, soft soldering, brazing, hard soldering, processing plastics

Planning and production of customer specific heating systems for automatic production processes

Advantages:

Unique product variety for all heating and production processes in the field of metal processing, and the processing of glass, quartz glass and plastics

Multifunctional, cost efficient solutions through the use of standard components and/or special torches

Automated solutions make accurate control of gas quantities and the production of exactly dosed gas mixtures possible ensuring reproducible quality for all oxyfuel processes and the widest variety of research and production applications

Complete range of accessories

Scope of supply:

Handles, shafts, injectors

Heating inserts

Forked, straight line and ring torches

Ignition and monitoring devices

Hardening torches

Accessories

High-Temperature Versatility for Industrial Needs

Engineered to reach temperatures up to 1300C, the Griflam Heating System excels in demanding industrial environments. It features interchangeable heating elementscartridge, tubular, or flexibleaccommodating a broad range of applications, from precision flame heating to robust thermal cutting. Its versatile cooling options (air or water) and heavy-duty electric motor ensure seamless operation for high-volume, high-precision requirements.

Safety and Efficiency, Engineered In

With integrated overheat protection and advanced insulation safeguards, Griflam prioritizes operator safety at every level. Its ISO/CE compliance, extended service life, and low-maintenance design contribute to reliable, long-term performance. This system can be installed on-site, supporting both indoor and outdoor certified operations, and providing a comprehensive solution for industrial heat and cutting tasks.

FAQs of Griflam Heating:

Q: How is the Griflam Heating System installed and supported?

A: The Griflam Heating System is installed by trained professionals with on-site support available nationwide. This ensures proper setup for maximum safety, reliability, and performance in your industrial facility.Q: What types of materials can be processed with this system?

A: Griflam is designed for precision heating and cutting of steel, iron, and alloy materials, with customizable system configurations to suit your specific application and material requirements.Q: When should the heating elements or system components require maintenance?

A: Thanks to its extended service life and low-maintenance design, Griflam typically requires only periodic checks and routine cleaning. Maintenance intervals depend on operational intensity and material usage but are generally much longer than for conventional systems.Q: Where can Griflam Heating Systems be used?

A: The system is certified for use in both indoor and outdoor environments, making it suitable for a wide variety of industrial applications, including flame heating, thermal cutting, and high-temperature processing.Q: What process controls and automation options are available?

A: Griflam comes with a manual control system as standard, with optional automatic features available for enhanced process management and consistency. This flexibility allows users to tailor operation according to their specific workflow.Q: How does the system ensure operator safety during use?

A: Built-in overheat protection and insulation safeguards prevent accidental injuries and equipment damage, while compliance with ISO/CE standards ensures safe operation under all certified conditions.Q: What are the primary benefits of using Griflam for industrial heating and cutting?

A: Industrial users benefit from precise temperature regulation, customizable cutting areas and thicknesses, rapid and uniform heating, high mechanical precision, and a durable, low-maintenance designdelivering reliable performance for large-scale operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in others Category

Circle Cutting Machine

Dimension (L*W*H) : Customizable

Feature : Other, Precision Cutting High Speed Easy Maintenance

Computerized : Yes

Type : Other, Industrial Cutting Machine

Drive Type : Electric

Capacity : High

Co2 Laser Cutting Machine

Dimension (L*W*H) : 3000mm x 2000mm x 1500mm

Feature : Other, High precision low maintenance

Computerized : Yes

Type : Co2 Laser Cutting Machine, Other

Drive Type : Other, Auto drive

Capacity : High

Terrablade Flame Cutting Machine

Dimension (L*W*H) : Standard Industrial Size

Feature : Other, Precision Cutting

Computerized : Yes

Type : Flame Cutting Machine, Other

Drive Type : Electric

Capacity : High

Bevel Cutting Machine

Dimension (L*W*H) : Customizable Dimensions

Feature : Other, Precision Cuts Low Waste

Computerized : Yes

Type : Other, Plasma Cutter

Drive Type : Electric

Capacity : High Precision Cutting

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS